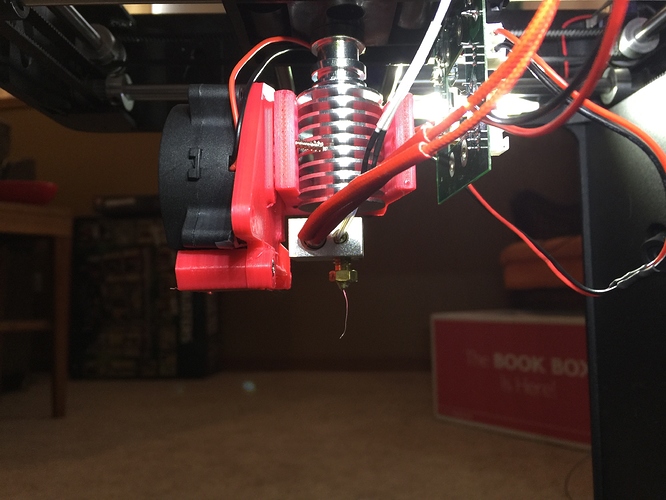

Wow. Your setup looks amazing. Congrats. I’ll get there eventually. But for now, I just want to put a single e3dv6 into the zim. So with a single e3dv6, I dont need to drill and tap anything? Do I use the big round heatsink that comes with the e3dv6? ---->

How do I mount the e3d using the zims nipple and a washer and how do I mount it without drilling and tapping? Where do I mount it to and which nipple are you referring to? Also, do I still need to put the filament extruder and feed motor on the back of the zims case? Or can i just leave the original zim’s setup where it is?

Im still a little lost so any help is appreciated. Btw, thanks for posting the pics and your zim looks really nice with those 2 e3d’s.