150 dollar zeepro that I bought from ebay.

http://www.ebay.com/itm/221926232723?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

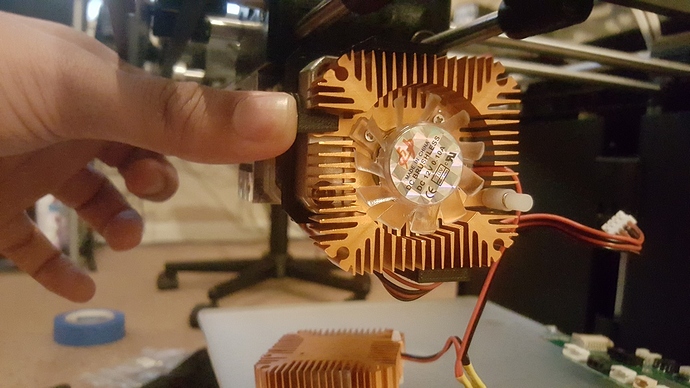

Above is the fan link.

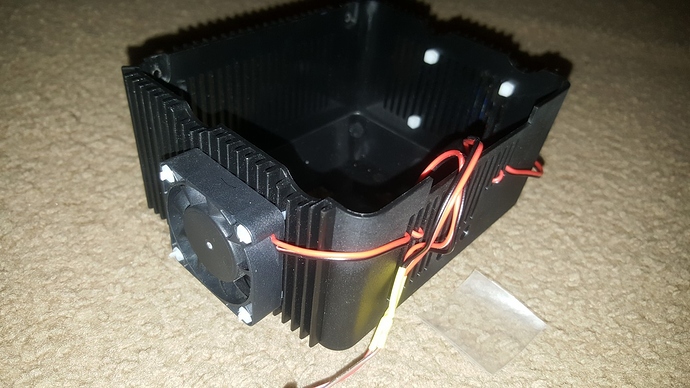

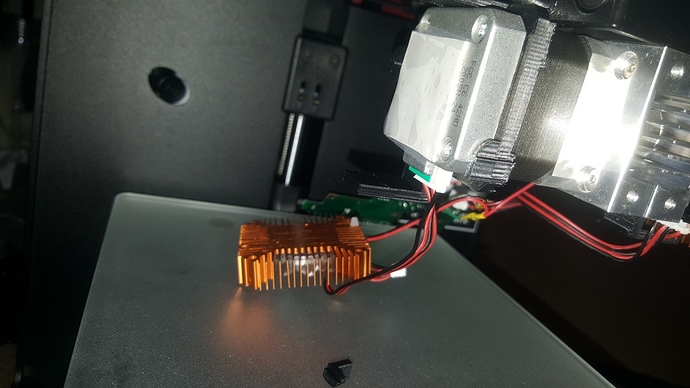

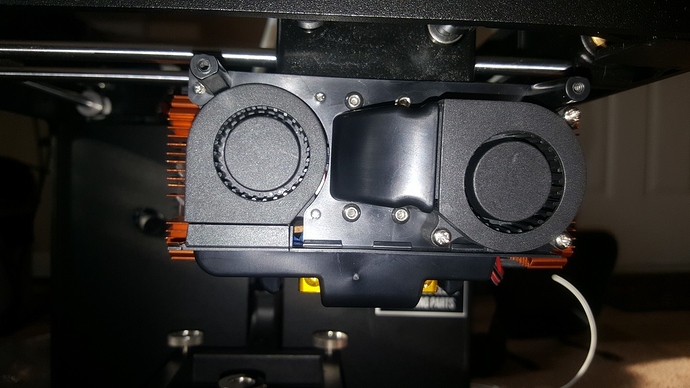

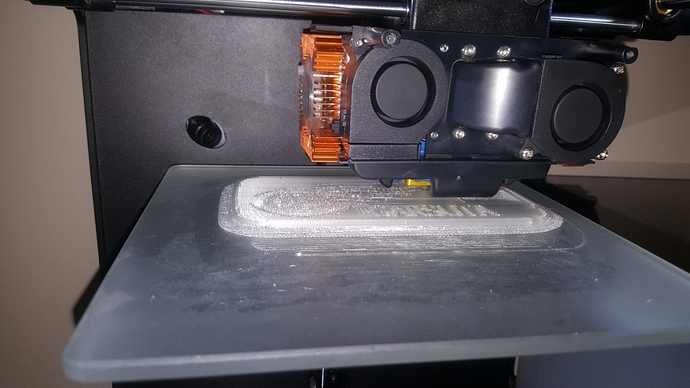

First modify your cover so you can print the file with ease by preventing you Zeepro from overheating like in the picture.

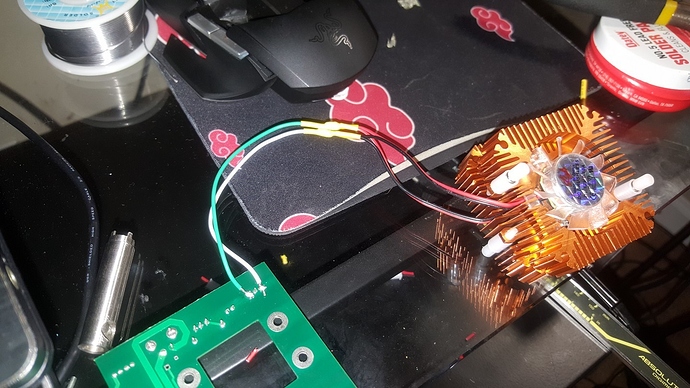

This fan is powered by the blue led command M1200 and its a 12v line found on the extraport on the extruder board.

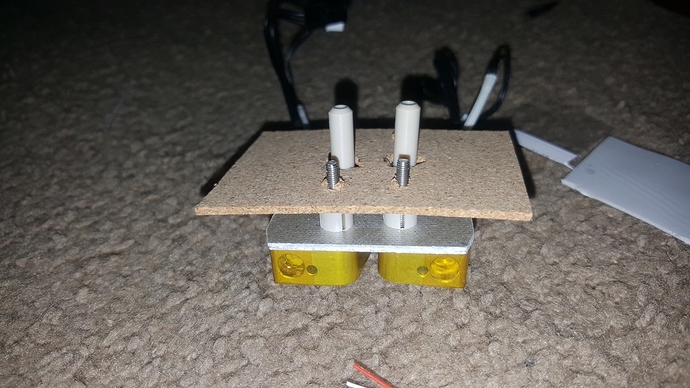

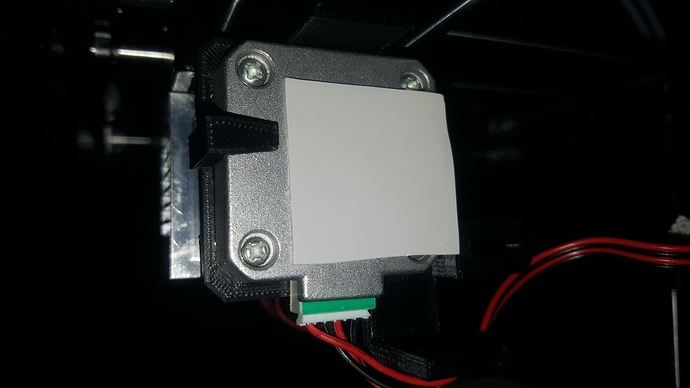

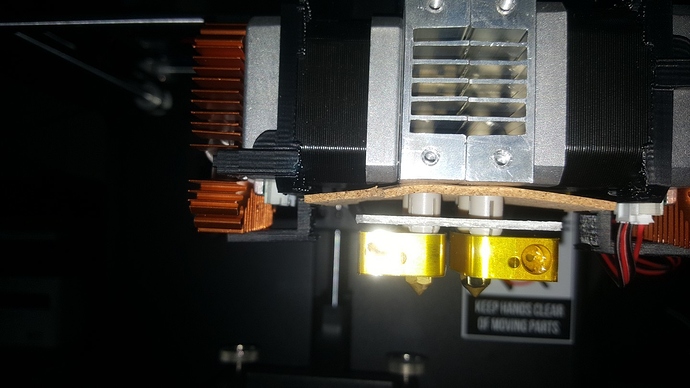

Protect you fan duct by putting a cork board that can reduce thermal conduction from your motor or extruder to the fan duck like in the picture.

Below are the link to the files please print a lot I recommend 6 or modify the google sketch files to make the fan adapter more sturdier Please share also:

https://drive.google.com/file/d/0B6VKEQJ3IFiZWGhaLWI4WTBsMW8/view?usp=sharing

https://drive.google.com/file/d/0B6VKEQJ3IFiZRWpYMkpZXzVHMU0/view?usp=sharing

https://drive.google.com/file/d/0B6VKEQJ3IFiZT0V0Qkg3djFmcDg/view?usp=sharing

https://drive.google.com/file/d/0B6VKEQJ3IFiZcGhidmlHZWNMRE0/view?usp=sharing

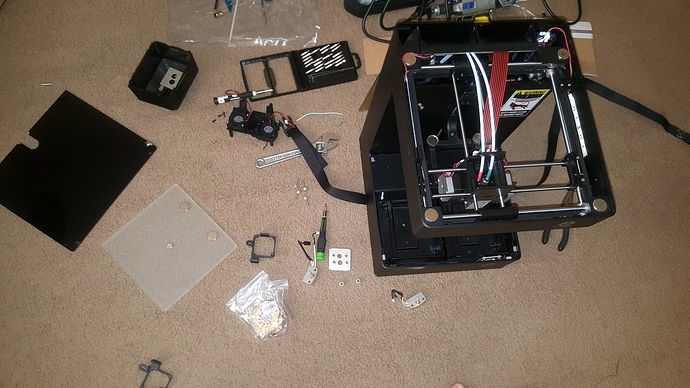

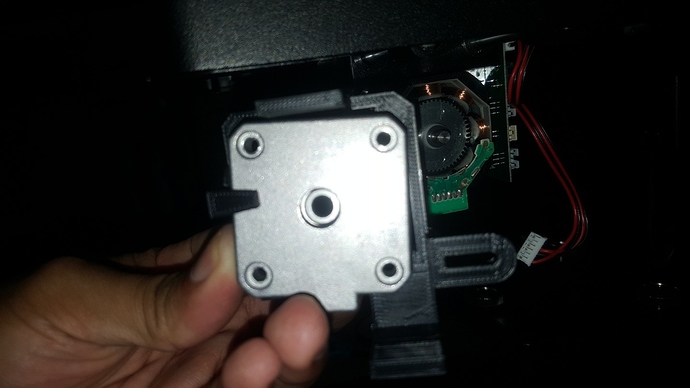

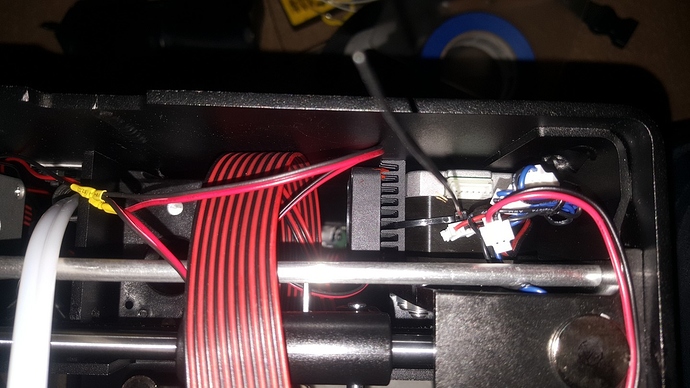

Disassemble all the parts just as you see in the picture.

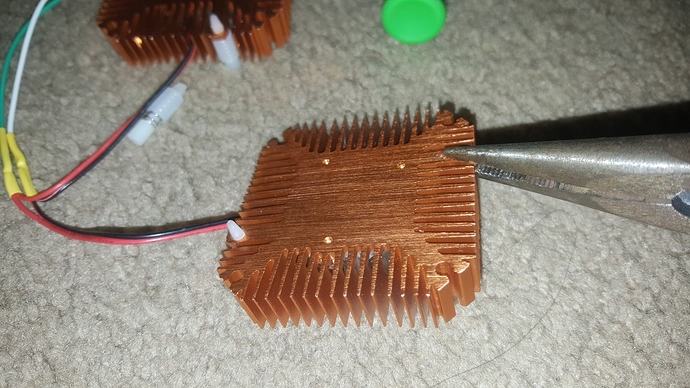

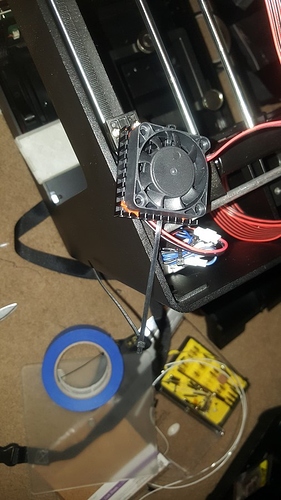

Here is the fan I use also. I also recommended to wrap your nozzle with a heat resistant tape to prevent excess thermal bleeding.

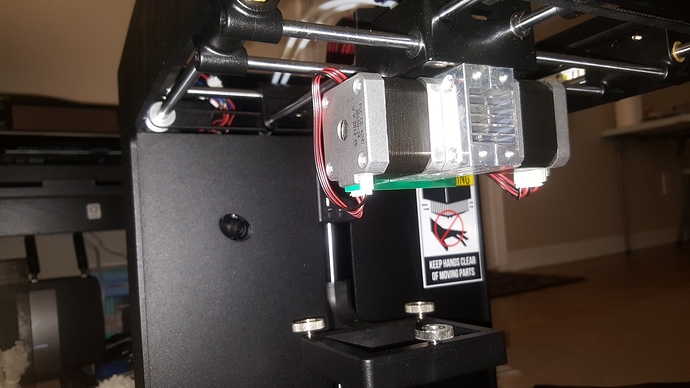

Remove the screw, and make sure you make an extra effort so you wont damage the crown of the screw as it is not that strong.

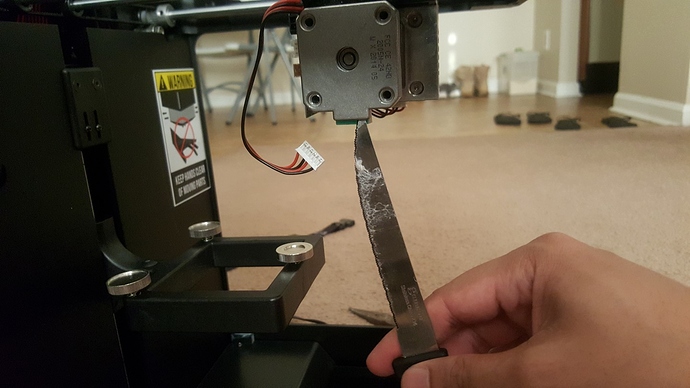

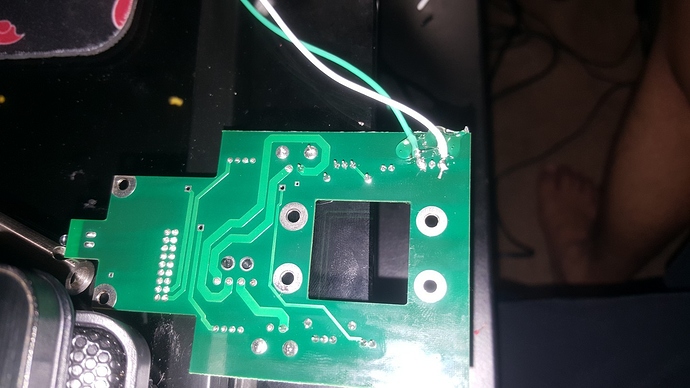

Pry it with the knife gently to remove the crown of the motor and don’t damage the PCB circuit board.

https://drive.google.com/file/d/0B6VKEQJ3IFiZWGhaLWI4WTBsMW8/view?usp=sharing

https://drive.google.com/file/d/0B6VKEQJ3IFiZRWpYMkpZXzVHMU0/view?usp=sharing

https://drive.google.com/file/d/0B6VKEQJ3IFiZT0V0Qkg3djFmcDg/view?usp=sharing

https://drive.google.com/file/d/0B6VKEQJ3IFiZcGhidmlHZWNMRE0/view?usp=sharing

here are the 3d printable files as well as the google sketch saved files for you to mod your fan adapter

The 3d printable files should look like this, unless modified.

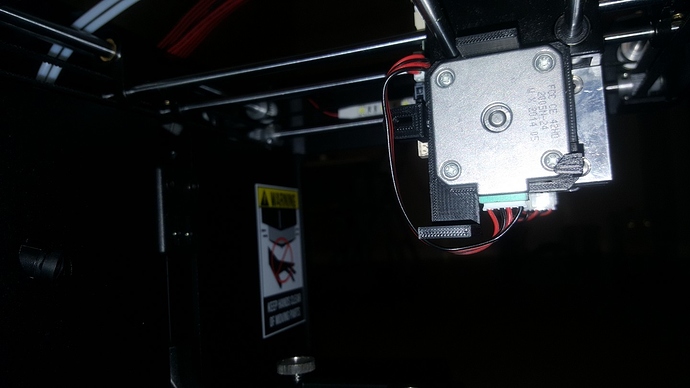

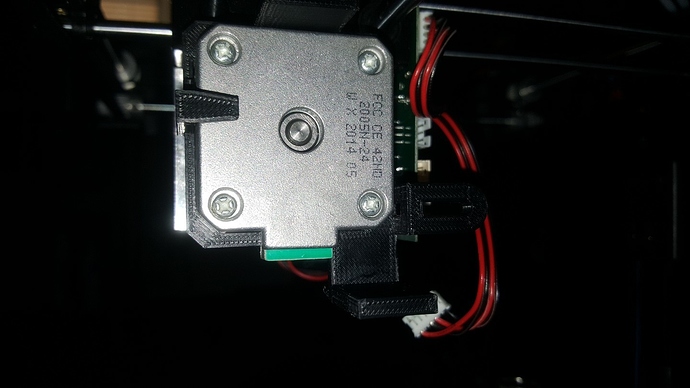

Put on the motor crown and attach the adapter to the motor carefully, it should snap on.

This is how it looks when the adapter is attached to the motor make sure you tighten the screw as its permanent.

Do the same thing to the left side

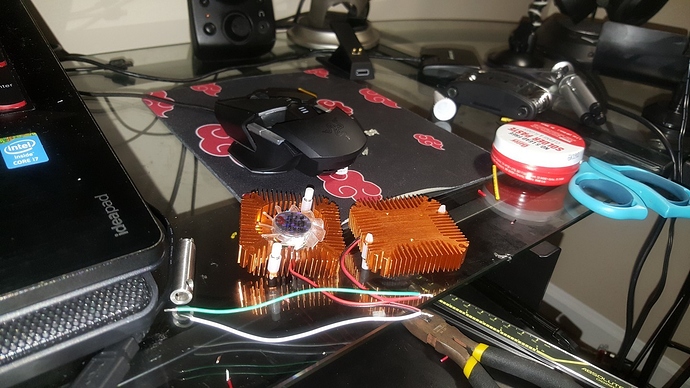

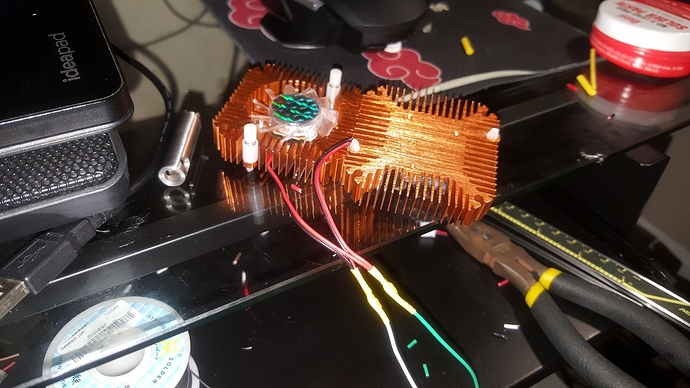

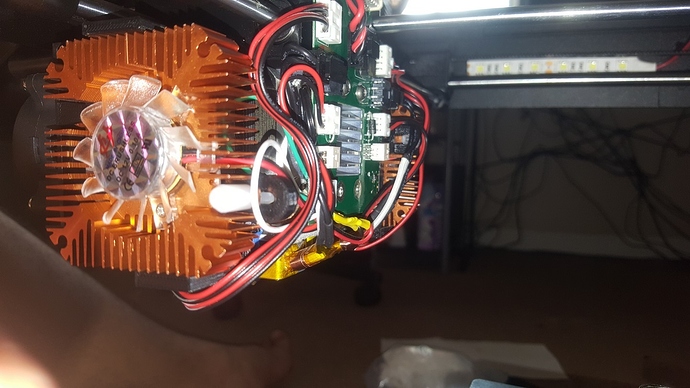

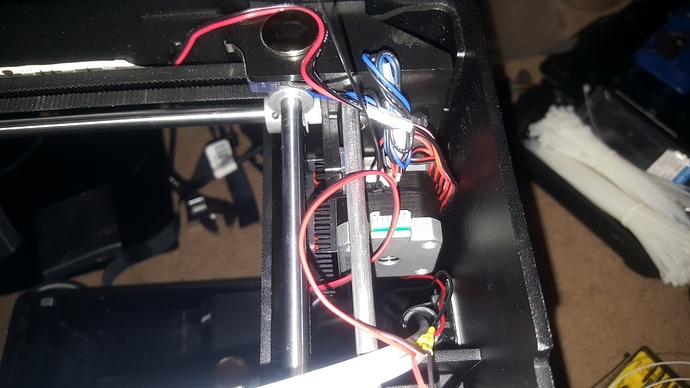

Solder the wire as you can see on the picture the fans are 12 volt gpu fan.

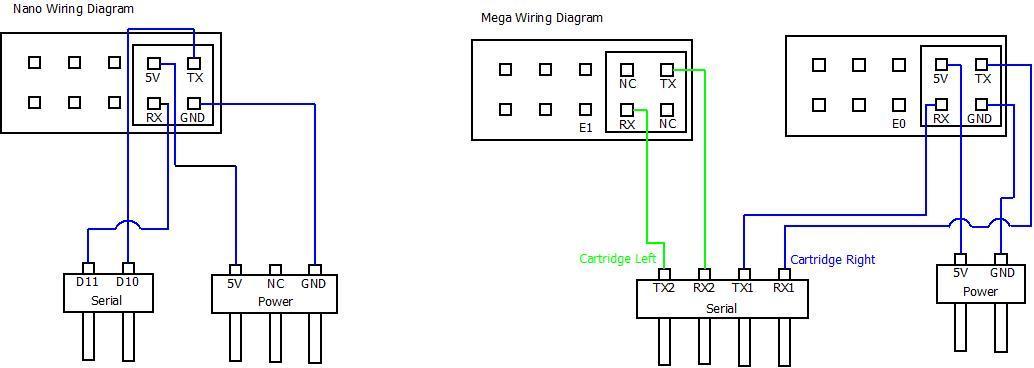

These are the pinout for your fan, pay attention so you wont see the magic smoke.

I advise to put glue stick so the wire wont break up easily during the process.

Bend the other connection a little bit to avoid stress on the adapter and it is recommended to print the adapter on ABS material or any heat resistant material.

Put on the heat pad I recommend an adhesive heat pad or thermal paste.

As you put your adapter try to support this part and avoid it getting stressed as it may break easily.

Here is a sample broken part. that’s why you should print a lot before trying.

Here is the finish part looks good.

Here are the X and Y axis motor cooler that I made, its a 5v brushless motor.

I solder the wire with 2 DuPont connector about 3/4 meter length just as in the picture

Remove the cover so you can install the motor.

I use a black nylon zip tie just to blend in the color but nylon is recommended.

This is how it should look.

Please see the 5v link to power your fan just look at this forum http://zeeproforums.technobly.com/t/zim-rfid-emulator/242

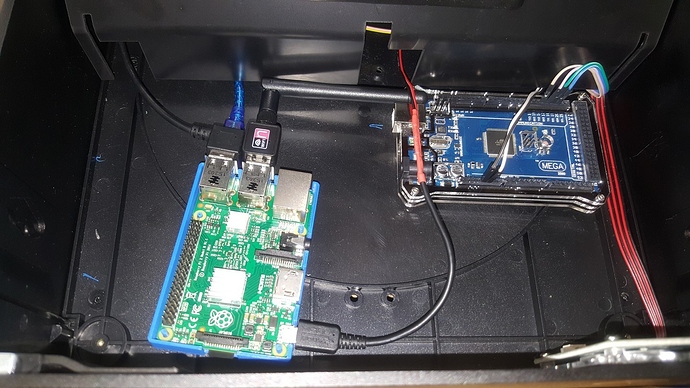

Here is my raspberry pi for octoprint and rfid emulator set up.

Cut the original cubie board power and solder it to a usb plug to power the raspberry pi. The advantage is when you turn off your printer, it will be off also and no extra power supply needed.

Here is my filament holder its the same concept as the zim use, you should prevent dust or its a must because it is one of the reason why extruders clogged. I highly recommend to buy 2 printer 1 for ABS and another for PLA to have flow and mixture consistency.

THIS IS THE ONE https://www.youtube.com/watch?v=vBHEnSkFA4g

GUARANTEED PRINTING AS LONG AS 24/7. AS LONG AS EXTRUDER ARE COOLED WITH THIS CONCEPT TCHNICALY IT SHOULD NOT STOP PRINTING.

*MAKE SURE YOU TUNE ALL YOUR STEPPER MOTOR DRIVER ITS THE DRV8825 TO ALL .25MV.

I HOPE THIS HELPS AS ZEEPRO IS ONE OF THE BEST AFFORDABLE 3D PRINTER, IT HAS DUAL COLOR PLUS GREAT PRINT RESOLUTION, PLUS WITH BUILTIN CAMERA,AND ITS LOOKS GOOD. PLEASE SHARE and MODIFY THE GOOGLE SKETCH FILE . THANK YOU VERY MUCH.!!