With Zeepro dissolved, this is no longer as useful, but I was just finishing up an RFID emulator to replace the cartridge system this week and thought I would post it anyway. Perhaps someone will still find it useful. This allows ripping out the lower feed stepper and cartridge holder, and has an option to provide infinite filament so the 200m limit won’t run out on large rolls. This is really only useful for the stock Zim A10 software, because the RFID can more readily be bypassed using Repetier, OctoPrint, or some other printing software.

I have uploaded 3 variants to github here: Zimulator

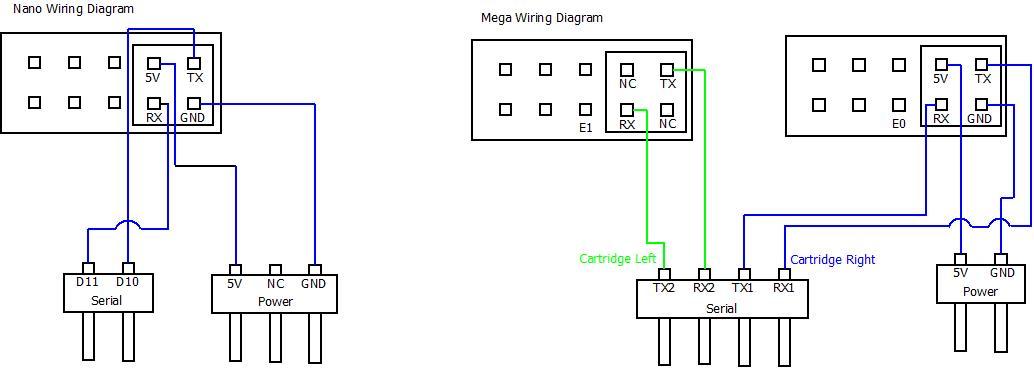

Nano is a single cartridge emulator - use two to simulate left and right.

Mega is a dual cartridge emulator.

Mega LCD is the same as Mega with an LCD interface for setting cartridge settings.

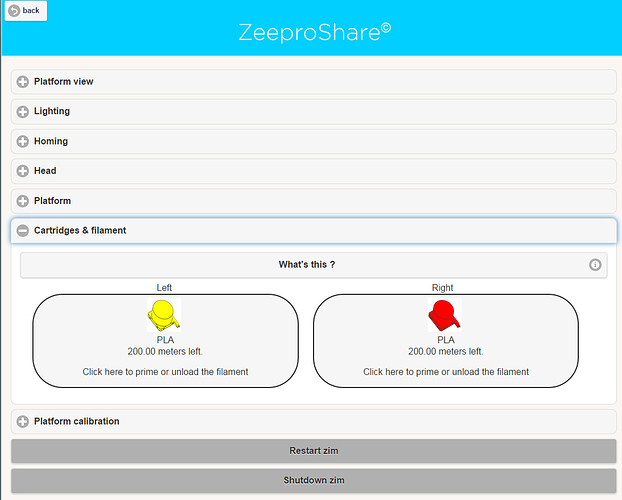

These run an Arduino Nano (1 RFID), or Arduino Mega (2 RFIDs). It emulates the YET-MF2 RFID mifare protocol, and stores the cartridge settings in EEPROM. You can use the manage cartridge menu as before, or there is an LCD version for use with a SainSmart 16x2 LCD that allows you to manipulate the cartridge settings without navigating to the “cartridge” URL.

I mainly did this because I had a mono extruder Zim I wanted to convert to dual, and the only thing I couldn’t find was the YET-MF2 RFID reader. I also wanted to make the Arduino track more than 200m of filament the stock firmware limits us to. So far this is not yet something implmented though, but hopefully soon. Finally, I hated having to navigate to that cartridge screen every time I changed a roll of filament.

Here’s a couple of pics of the hook-up.

Two Nano’s for left and right…

Or a single Mega for left and right…

Removes the need for these things: