Ok heres the first tests!

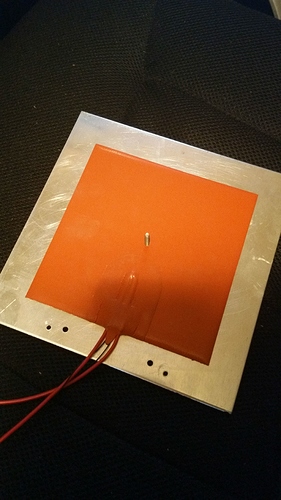

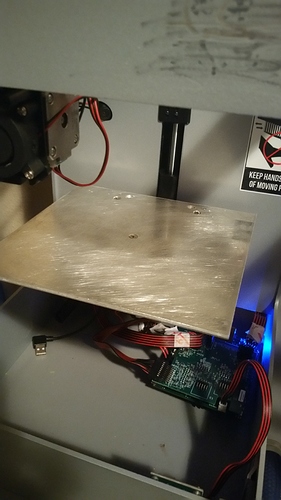

Its adhered to a 1/8th aluminum plate. Just stuck it on. It measured 1 ohm and at 12v its pretty much 150watts. I chose 150w because the goal is to pass it through the board. GASP! I know I know, risky but a relay is still an option. The heat pad is only 150mm x 150mm leaving a 50mm aluminum border. I couldve gone bigger but decided not to. Includes a standard 100k thermistor internally. Mounts using the existing holes and nuts but added a longer screw. I will be including much longer screws to allow thumb wheels on the bottom for easier leveling.

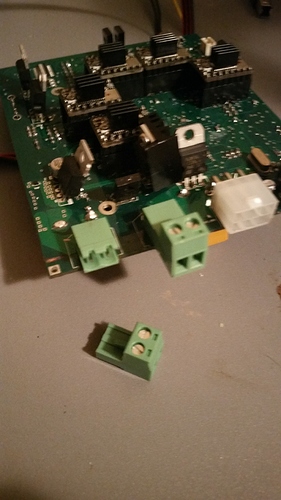

I should mention I am not using the puny stock power brick but instead a 500w pc power supply. I will include a 2-post screw terminal to replace the “BED Input” jack (See pictures) if you do not want to buy a proprietary power supply

Here’s the results from a straight connection to a 500w pc power supply measured with a IR laser thermometer :

Start: 29C

1 min: 46C

2 min: 60C (too hot to hold)

3 min: 72C (Too hot to touch)

3:30 : 80C (ABS temps)

4 min: 85C

5 min 92C (Near temp plateau)

5:55 100C (Near max temps, I think)

Let me know what you guys think!

? I hope I dont blow the whole building down.

? I hope I dont blow the whole building down.