Looking great! What happened to your “Zeepro” logo?

Create your own heated printbed!

If you have ever seen Arduino board sockets “melting” like mine at my RepRap you will definitely use a relais

Have you looked at the uniformity across the build plate at all? Are you satisfied with it?

Are you selling the power supply separately? I have a 400W PC power supply already, and I’d like to avoid shipping costs and use the one I have.

I would have thought 120W would be better to pass through the board… (10A)

I bought it used. Somebody hated the company!

I have melted a board before… and I’m realizing I wont be able to buy a replacement board and drop it in. Relay it is!

There is not a lot of uniformity due to the edges but I kinda like it that way. The heat dissapates on the edges while the center maintains temp. I just don’t expect my electricity bill to go down.

What was your strategy for drilling a hole through the pad? Is it safe to drill anywhere?

The Pad that I got came with the hole predrilled. I would think that if you drill in the wrong spot you will cut the wiring inside and it won’t work.

That is what I thought! Some of the cheap thin mats you can see the wire loops so it might not be so bad. I can’t find any with holes though… Any chance you have a link kicking around?

I don’t remember where I got mine sorry.

Anyone recommend using the items below to build a heated printbed? I just purchased my printer and looking to find the easiest way to rig a heated bed without too much trouble… My only concern is addressing how to turning off the heated printbed after the print is completes using the controller below…

http://www.amazon.com/3D-Printer-Aluminum-3-Point-Adjustment/dp/B019BGAB7K/ref=pd_sim_sbs_328_11?ie=UTF8&dpID=31GBiW%2B64hL&dpSrc=sims&preST=AC_UL160_SR160%2C160&refRID=1AC0HV6EY69FSVEQC7E2

http://www.amazon.com/3D-CAM-Anodized-Aluminum-Carriage/dp/B01A974GIU/ref=pd_sim_328_3?ie=UTF8&dpID=4128n768G9L&dpSrc=sims&preST=AC_UL160_SR160%2C160&refRID=0VZ7ZW155BPRFARN00G7

Thanks,

-Brian

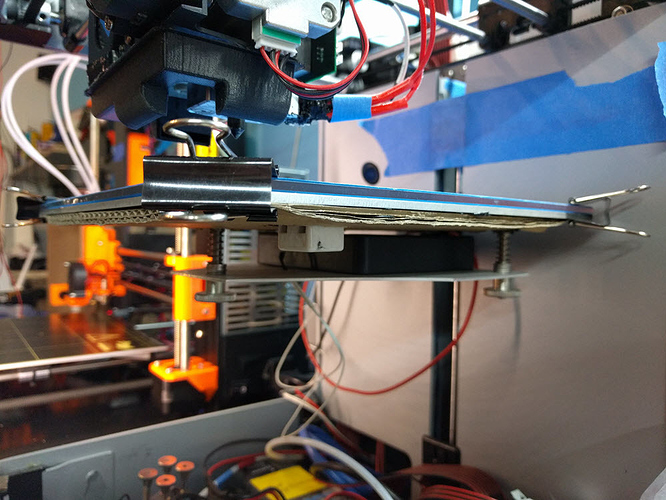

As creating a heated printbed seems to be a big thing for some users and as I’m the creator of this topic (and the wiring diagramm on top) I would like to share my solution which works brilliant so far: several hundred of hours printed so far…

- The wiring is done exaclty as on the diagramm

- sheet metal and mounted it via the 3 holes in the plastic piece of the z axis

- wood thread inserts glued on the printbed (just over the 3 springs) -> use high temperature silicone as a glue!

- the white porclain connector was intended to hold a temperature fuse but never used

- standard MK3 printbed with cupboard isolation underneath