@Opera

Trying to setup a zim cloud slicer on your own to use would honestly be harder than setting up a raspberry pi running octoprint (which is simply referred to as octopi). A 3d printer that anyone can use is great until that company goes dark. this is the situation we find ourselves in now.

I tried to pull everything in one spot that people would need here : Zim customized software/hardware quick guide It is not quite a step by step guide but it is pretty close. I can add more details to it as I have time.

I will say that. I had so many problems using the zee pro software getting things to print well. I am now printing part after part with higher quality than i ever got before simply by unplugging the left zimboard and adding the octoprint. My camera is now smooth and no longer pauses/hangs or stutters constantly. I also can get up and printing faster. I had maybe 1 or 2 good prints and 15-20 failed prints when using zee pro ui. With my new setup i’m on my 8th part and Zero failures so far. What has completed is coming out much higher quality and the parts are much more complicated. The support structure generated in Simplify3D is 10x better than what the ZeePro software generated. The support doesn’t fall over for me and is easier to remove. It leaves me with a clean part.

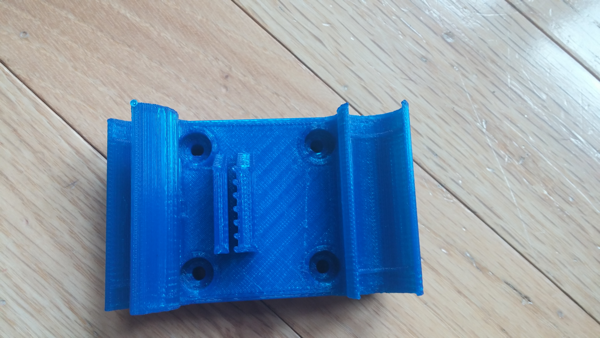

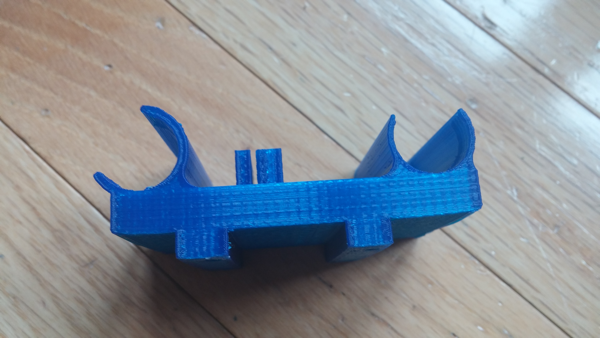

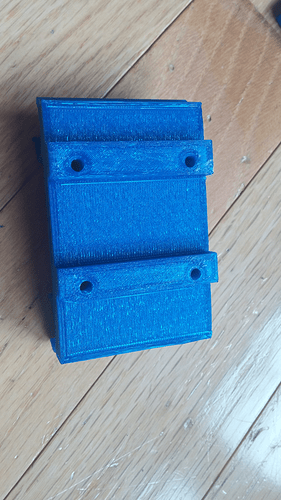

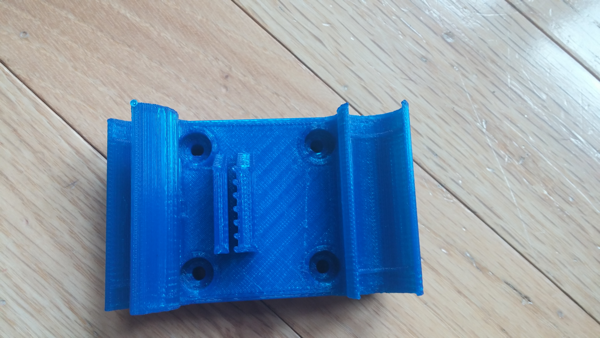

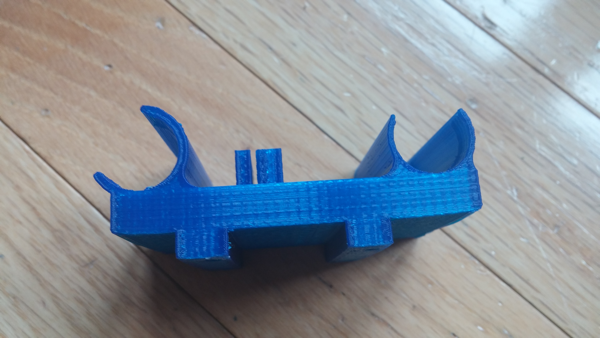

Here is a part that just completed: Hopefully the detail shows up. It’s cheap $15.00 2kg filament spool i picked up at micro center. It’s a bit shiny and reflects light so the picture quality might not reflect the quality of the part. The parts are smooth and not too rough. The support structure took 15 seconds for me to remove in 4 different spots and you can’t really tell where it was.

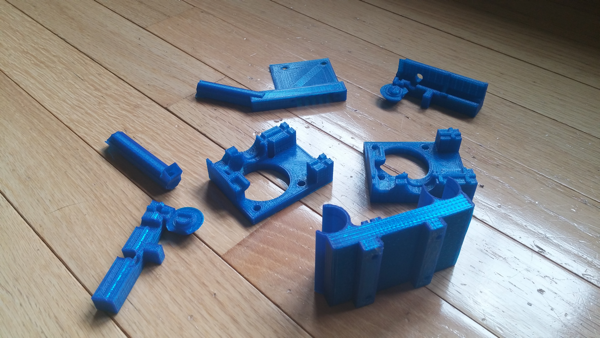

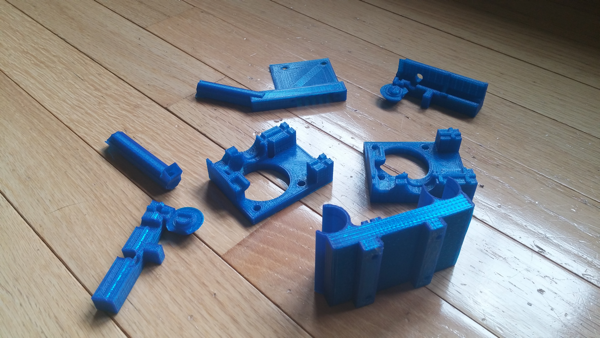

Here are the other parts I printed using zero support structure (minus the part shown above). The holes in my parts are round and clean unlike before. 2 parts contained tubes and they printed with no support and didn’t sag when the tubes were closed.

I will/would not go back at this point. I had zero printing experience prior to this Zim. It’s a bit harder to get up and running with the new setup but so worth it.

Basic outline is:

One time only:

1.Get a raspberry pi and add octoprint

2. unplug left usb board. (power & usb camera)

3. plug in usb camera and wifi device to raspberry pi and power it up.

4. unplug usb port at back of zee pro zim. plug cable from that to raspberry pi

5. connect to octoprint in browser and use interface to connect to zim.

Whenever i want to print now.

- power on raspberry pi

- power on zim (i might power raspberry pi off zim later so i can just use the Zim power switch.

- upload gcode using octoprint. (I use simplify 3d to generate gcode) I haven’t tried the built in slicer located in octoprint. Mainly because I haven’t created a printer profile yet.

- hit print

Hard part:

- If not computer savvy; Initial setup of octoprint with wifi adapter (you can just use USB and plug printer to Raspberry PI

- Unplugging the USB port. It was easy for me but i took my time and was careful removing the plug Zeepro put in.

It doesn’t get much easier to use the Zim this way. Octoprint is faster to respond and I get higher quality parts. I am not intimidated by choosing models off thingiverse and don’t look at them and think ‘thats too complicated or support structure will be impossible to remove if i do try to print it’

Like I said, I’ll try to go back and update my thread to make it even easier when I have some extra time.