After doing some reading online I have read some other techniques for unclogging nozzles, but they were for other printers that didn’t have the plastic/silicone/whatever tube sticking out of the nozzle. Do you think they won’t work or will ruin the other part? One technique was soaking in acetone, and the other one was to straight up burn out the plastic with a blowtorch. Do you think it the zeepro nozzles could take this kind of abuse? The heat and push out technique didn’t work so I don’t have any other options anyways.

Unclogging Nozzle

I would not recommend that.

The problem of a partially or complete clogged nozzle is not some plastic, but some particle else.

Otherwise you would be able to push out the plastic with the recommended methods.

So buring the plastic furthermore…I doubt it improves anything. I would expect some residue burned in forever.

Acetone only works for ABS. But in the end same problem…does not remove foreign particles.

Only real solution is disassembling the nozzle parts and drilling it open again with a 0,3mm and 1,8mm drill.

All my clogged nozzles, results from weak filament drive, can easily be resolved by the “heat up and manually push out filament” method.

Does anyone know where I can buy more nozzles for the zeepro? Is the nozzle we need a proprietary design? I would love some fresh ones to start printing with again. I see super cheap nozzles on ebay but they don’t have the extra piece on them that ours do.

Zeepro (possibly the company formerly known as) used to sell nozzles in the spare parts section of their website. They claim these are custom made for Zeepro. Assuming they are still in business, you can order more from there. It doesn’t look like they are, however. I think getting another one to work may entail redesigning the heater block and the guide tube on top of the nozzle. This seems a bit drastic, but if Zeepro has gone down in flames, it may be the only solution.

What you are describing (redesigning heater block) sounds pretty complicated, do you think the casual user is now screwed? Being able to buy new nozzles seems pretty important over time.

I guess Zeepro is dead…

(and I still do not understand why everyone is so calm  )

)

Redesigning the heater block should not be a big deal but it’s time-consuming and also does cost some bucks.

I would have everything at home/at my work to do so but I’lll see how much users do want to have spare hotends. Basically I only would change the brass/Peek part and replace it to standard nozzles (dismantled everything and it would just need a redesigned brass part…

I’m pretty confident I can keep my Zim up and running for as long as needed, so I wasn’t as concerned about Zeepro’s ability to plan and run a business. I actually thought their business plan, as posted by Breega during the series A, was a bit sketchy from day one. I’ve been in similar VC funded ventures, so it was not entirely unexpected they would crash and burn.

I also always expected these printers would require some tweaking, fabrication, and fixing. Making new nozzles would be part of the fun for me to keep it going. I understand the disappointment though. I’d be more disappointed if I bought one off of Amazon, paid full price, and then Zeepro went silent and stopped selling cartridges, parts, and providing support without a single word. In that case, it would have been an exceptionally raw deal indeed. My guess is they didn’t sell that many through retailers, so the set of truly disgruntled customers is small.

I guess everyone is so calm because we all felt it was inevitable

I dug out the box that the heated bed came in last week (July 7th delivery) and I noticed there was a phone number in the return address. I called the number and the person that answered said he no longer worked for the company, but will try and get in contact with them and find out why they have not responded. We will see what transpires

Do you know what the name of the plastic looking piece sticking out of the nozzle is called? It’s a long shot but I want to scour alibaba to see if the people that manufactured the nozzle for zeepro tried to also sell them wholesale afterwards. There must be certain specs that the nozzle needs, can anyone share them with me? I promise to share anything I find.

**I also posted this on the kickstarter but you guys might not know better:

I really hope we can find an easy way to use other parts or to find who manufactured their nozzles and see if we can get some made for us. The nozzle ‘jacket’ or plastic looking piece that is sticking out, is this something any other printer uses? I wonder if we could find a tool to remove it (it has 4 small holes and looks to be threaded in), it might be a lot easier to unclog the nozzles if we could remove it. I’ve seen tools that would work to remove something like the threaded insert but they were much bigger (for bike repair), I wish I knew what it was called so I could begin my search.

I believe its the material is “peek”. (Dont quote me on that)

I can see about drawing up some cad drawings of the parts this weekend.

Not sure whats going on. My printer has been working great for months, but in the last 72 hours its gone to shit and cant print.

I also had the problem with a clogged nozzle but could solve it:

( Maybe it also works without unscrewing the nut - #3 )

1.) Unscrew the heater block from your Zeepro - and don’t loose the brown sleeve which is on the brown extruder sleeve

2.) unscrew the brass nozzle from the heater block

3.) unscrew the flat nut (the one with the 4 square holes): it’s hard but I successfully did it with the two edges of a small electronic plier ( that one: http://www.boersch-werkzeuge.de/KNIPEX-Elektronik-Seitenschneider-Super-Knips)

4.) take a 2,2mm twist drill and remove all filament deposits from the internal channel

5.) if you have a 0,4mm drill at home also gently drill the nozzle itself

6.) remove all debrits from drilling and look into the noozle from the brown plastic side: does shine light through the tiny hole at the top? yes -> reassemble it!

At my ZIM a small part of the white Teflon tube which is located in the brown PEEK has slightly blocked my nozzle: after re-drilling it everything was fine again!

((( I’m still wondering how long this forum will stay online as it seems Zeepro is dead… )))

long story short, I took apart the nozzle today to clean it, just want to share some picture with you guys.

The assembly…

This paint & epoxy remover seems to work pretty well getting the PLA soft.

followed martinking’s instruction using a small drill to get the hole to open up again

it seems like it is best to use hand and slowly twist in the drill, so you don’t damage the nozzle…

Btw, I broke one of the heater block they are quite easy to get un-threaded so becareful.

Thanks Winston, good info.

Yep, I spent about 30 mins one night trying to cleanly thread a nozzle back into the heater block. It is almost easier to cross thread than it is to thread correctly. Lately I just remove the whole heater block and work on it, instead of just the nozzle.

Hey jpod, thanks for the comment. Ya. Aftet doing this three times today I found out it wasnt the nozzle, apparently my extruder gear have a hard time gripping the filament

More debugging tomorrow!

What tool did you use to unscrew the nozzle and peek?

I am still having big problems finding something that works well without damaging it.

how did you remove the plastic from the nozzle ?

thnks

Roberto

It is displayed and mentioned in the post: Paint and Epoxy Remover.

It probably contains Methylene Chloride which makes PLA softer.

Just noticed that Methylene Products have been banned in Europe

Thanks for the info, could you post some instructions / photos of how you removed the lockring on the nozzle? I went and bought some lock ring pliers at someone’s suggestion but I could get it to move. I would love to find something that grabs all 4 holes, I know if I can get it open cleaning it out would be the easier task.

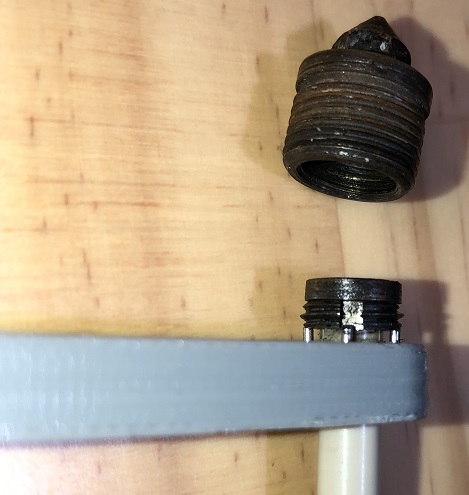

Hey guys sorry for the late reply! Here is a picture of the tool I used

I am not sure if there are 4 hole grabbing, I do know if you use the heating block to heat up the plastic it would be much easier to unscrew!

p.s. channellock 927 8-inch retaining ring plier is the name.

I made this;

Please refer following link if you are interested;

https://www.thingiverse.com/thing:4542658/files