When printing something larger or multiple parts that are near the print area border, the print paths are reflected.

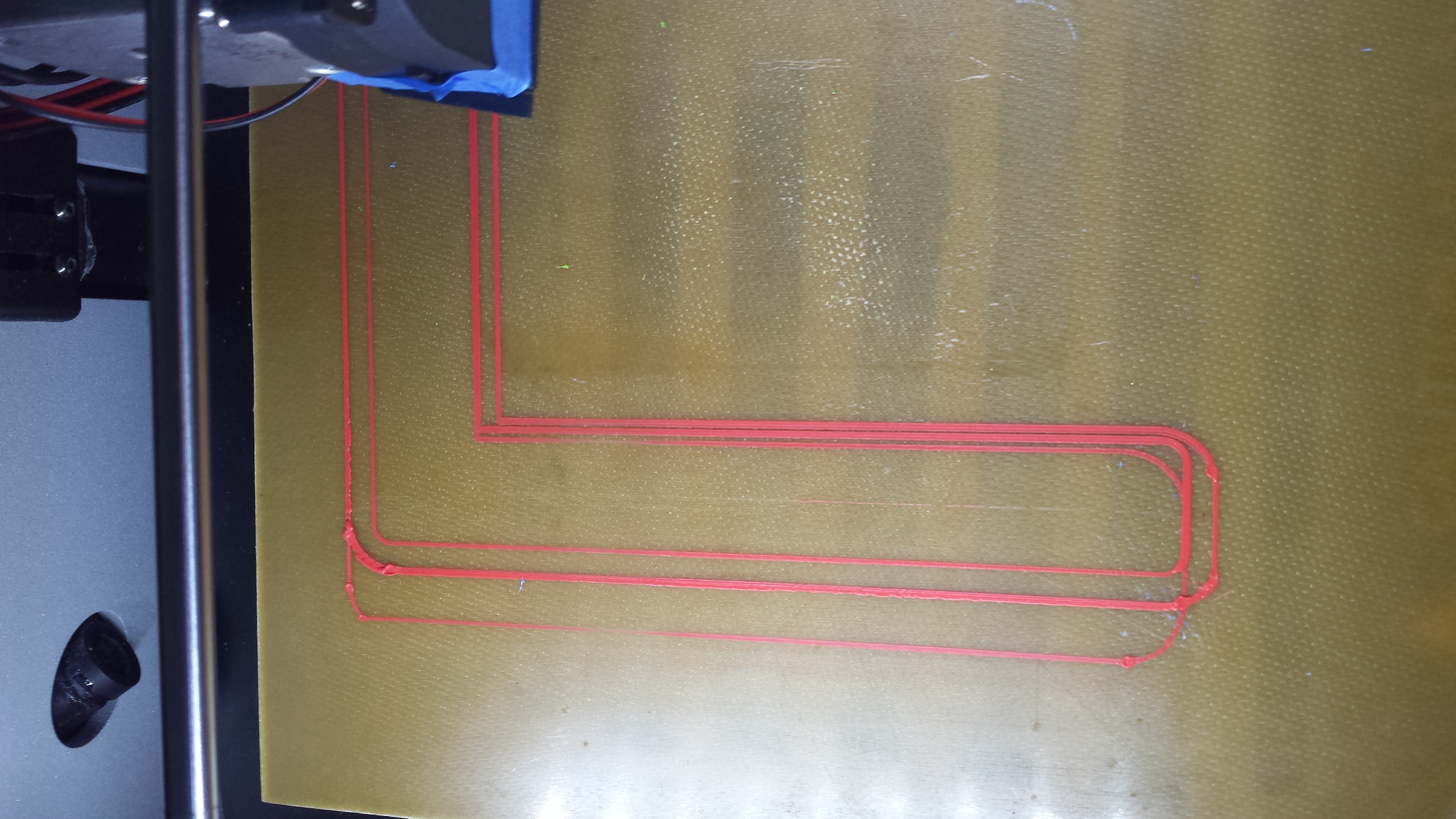

The print I tried should be one rectangular piece. What happened is that every circle the print continued moved. So in the picture you see three rectangular shapes instead of one.

Here is a picture to better understand what I mean:

Furthermore you can see a few blobs along the line. This is where the print head stops for one second and then continues and without retraction makes this blob. This always happens during my skirt and less during the rest of the print but still it does happen.

My print bed area is set to 140x140x138 (X/Y/Z).

It happened with Zeepro Software and Slicer and now with Octoprint. So it seems some hardware thing, or not?

Anyone know where this comes from?