Hey 3D, is it the export bundle?

if it is, try this link https://www.dropbox.com/s/59dfnqwdlecvi7s/Slic3r_config_bundleWW.ini?dl=0

My mileage is quite low on ZeePro, with about 2 days of use after a week and half of troubleshooting (got a salvaged unit on cragslist).

This unit did not work well with the ZeeProShare interface. Due to a very specific Zee board problem which resulted in Z stepper motor random stepping at higher RPM. I could print at low RPM (2-3mm/s) but after 2 days I replaced the board with another salvaged ZeePro printer. Which solved that crazy motor stepping issue. With the slic3r default, and preset mentioned here my right nozzle was printing well.

Then I tried to print with the left nozzle, and problem surfaces once more.

After few days troubleshooting I found out the gears that’s driving the filament is having serious slipping issue. Sometimes it lose the grip for a few seconds even without any resistance, core filament not advancing while the motor still turning. resulting in this kind of stuff

people thought it was nozzle clog, but it wasn’t. I cleaned the thing inside out, with drill bits and sonicator. put everything back together, and exactly the same cube prints.

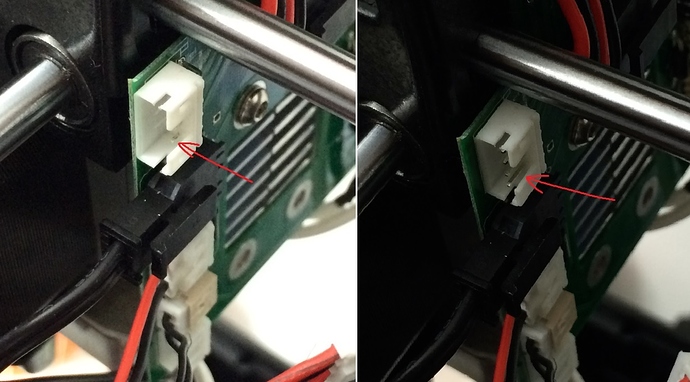

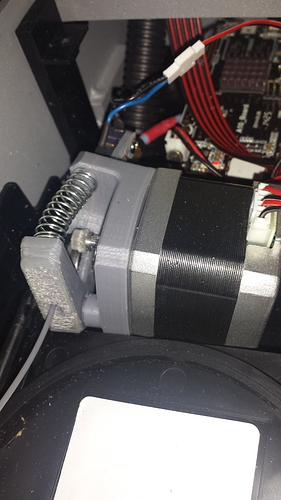

just some pictures to share while I was doing the take apart.

Anyways, pretty much disassembled the block, cleaned the gear teeth, reassembled everything tightly yesterday, and today the “right nozzle” is working great, was able to get a 6 hours of printing none stop.

This is one of the print I did today, too bad I can’t show you guys other stuff due to NDA.

I havent get around to get another spool of filament to test the left extruder, which was the bad apple “slippage problem”. my other spool is coming tomorrow, I will let you guys know how it goes, if it is gone good news, if it is still doing this kind of shibang

then I really dont know what to do with the slipping problem.

. So I hooked the fan on to a 9V battery and turn the fan on manually when it is doing a lot of overhang,

. So I hooked the fan on to a 9V battery and turn the fan on manually when it is doing a lot of overhang,