I had been asked by one of the members here to post my settings, and figured id show off some of my prints while I’m at.

I copied my settings into slic3r and had it post a config file. But i only changed the settings in slic3r that there was access to change inside of zim.

settings-

generated by Slic3r 1.2.9 on Sat Jul 18 12:08:12 2015

avoid_crossing_perimeters = 0

bed_shape = 0x0,200x0,200x200,0x200

bed_temperature = 0

before_layer_gcode =

bottom_solid_layers = 3

bridge_acceleration = 0

bridge_fan_speed = 100

bridge_flow_ratio = 1

bridge_speed = 60

brim_width = 0

complete_objects = 0

cooling = 0

default_acceleration = 0

disable_fan_first_layers = 3

dont_support_bridges = 1

duplicate_distance = 6

end_gcode = M104 S0 ; turn off temperature\nG28 X0 ; home X axis\nM84 ; disable motors\n

external_fill_pattern = rectilinear

external_perimeter_extrusion_width = 0

external_perimeter_speed = 50%

external_perimeters_first = 0

extra_perimeters = 1

extruder_clearance_height = 20

extruder_clearance_radius = 20

extruder_offset = 0x0

extrusion_axis = E

extrusion_multiplier = 1

extrusion_width = 0

fan_always_on = 0

fan_below_layer_time = 60

filament_colour = #FFFFFF

filament_diameter = 1.75

fill_angle = 45

fill_density = 30%

fill_pattern = honeycomb

first_layer_acceleration = 0

first_layer_bed_temperature = 0

first_layer_extrusion_width = 0

first_layer_height = 0.25

first_layer_speed = 40%

first_layer_temperature = 190

gap_fill_speed = 15

gcode_arcs = 0

gcode_comments = 0

gcode_flavor = reprap

infill_acceleration = 0

infill_every_layers = 1

infill_extruder = 1

infill_extrusion_width = 0

infill_first = 0

infill_only_where_needed = 0

infill_overlap = 0

infill_speed = 80

interface_shells = 0

layer_gcode =

layer_height = 0.15

max_fan_speed = 100

max_print_speed = 80

max_volumetric_speed = 0

min_fan_speed = 35

min_print_speed = 10

min_skirt_length = 10

notes =

nozzle_diameter = 0.35

octoprint_apikey =

octoprint_host =

only_retract_when_crossing_perimeters = 1

ooze_prevention = 0

output_filename_format = [input_filename_base].gcode

overhangs = 1

perimeter_acceleration = 0

perimeter_extruder = 1

perimeter_extrusion_width = 0

perimeter_speed = 40

perimeters = 3

post_process =

pressure_advance = 0

raft_layers = 0

resolution = 0

retract_before_travel = 2

retract_layer_change = 0

retract_length = 1

retract_length_toolchange = 10

retract_lift = 0

retract_restart_extra = 0

retract_restart_extra_toolchange = 0

retract_speed = 40

seam_position = random

skirt_distance = 5

skirt_height = 1

skirts = 1

slowdown_below_layer_time = 5

small_perimeter_speed = 75%

solid_infill_below_area = 0

solid_infill_every_layers = 0

solid_infill_extruder = 1

solid_infill_extrusion_width = 0

solid_infill_speed = 75%

spiral_vase = 0

standby_temperature_delta = -5

start_gcode = G28 ; home all axes\nG1 Z5 F5000 ; lift nozzle\n

support_material = 1

support_material_angle = 0

support_material_contact_distance = 0.2

support_material_enforce_layers = 0

support_material_extruder = 1

support_material_extrusion_width = 0

support_material_interface_extruder = 1

support_material_interface_layers = 3

support_material_interface_spacing = 0

support_material_interface_speed = 75%

support_material_pattern = rectilinear-grid

support_material_spacing = 2.5

support_material_speed = 100

support_material_threshold = 0

temperature = 180

thin_walls = 1

threads = 2

toolchange_gcode =

top_infill_extrusion_width = 0

top_solid_infill_speed = 50%

top_solid_layers = 3

travel_speed = 100

use_firmware_retraction = 0

use_relative_e_distances = 0

use_volumetric_e = 0

vibration_limit = 0

wipe = 0

xy_size_compensation = 0

z_offset = 0

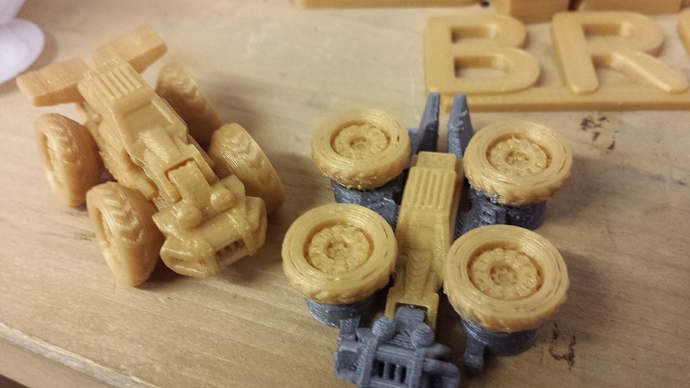

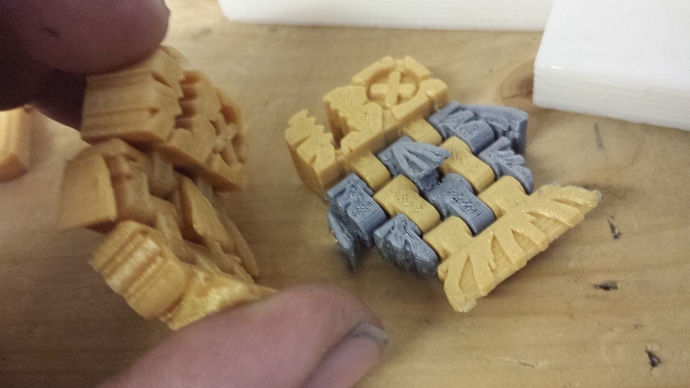

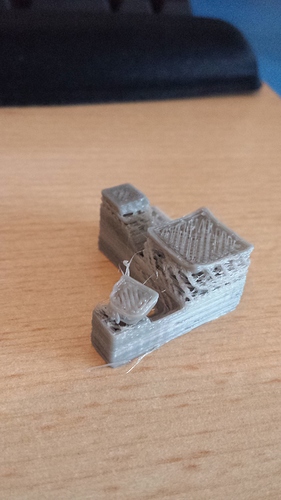

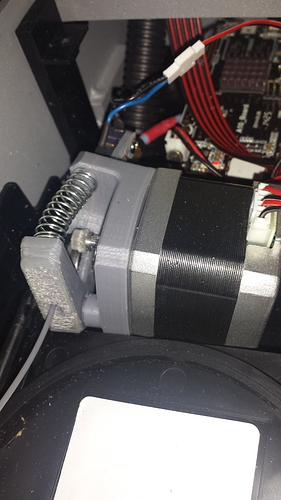

Here are some pictures of parts i printed, all with the exact same settings described above.

[edit]

more pics

seems like you got it covered. Thank you so much

seems like you got it covered. Thank you so much

. So I hooked the fan on to a 9V battery and turn the fan on manually when it is doing a lot of overhang,

. So I hooked the fan on to a 9V battery and turn the fan on manually when it is doing a lot of overhang,