@Insomnia, I’m in for a couple of these. Looking great!

Custom hot ends for the Zim

Thanks insomnia - I had the same idea

I also thought of reworking the existing heater blocks as I do not have a CNC mill around.

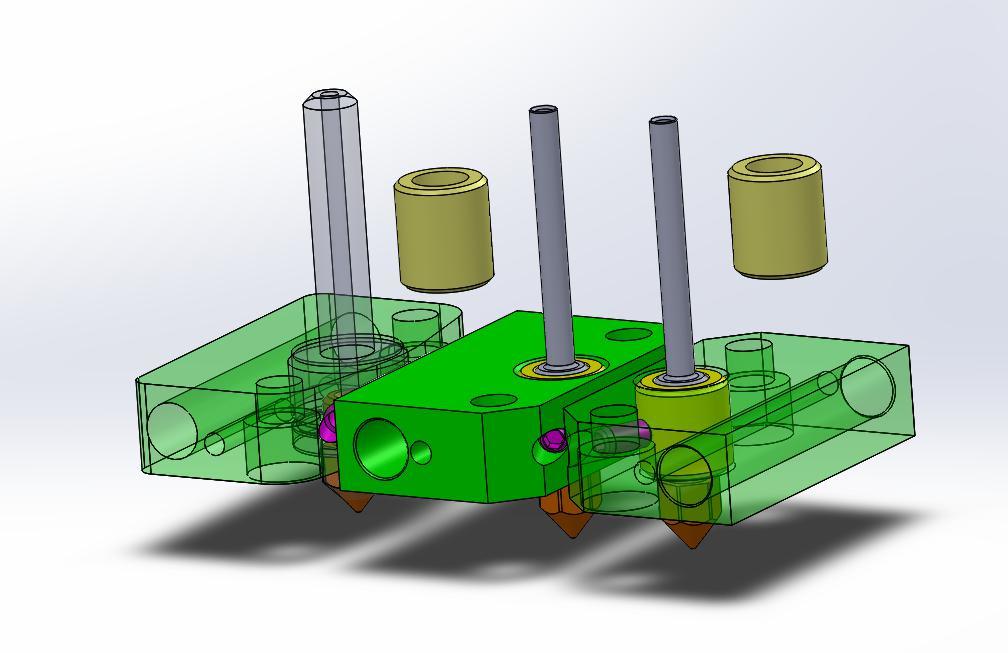

2 alternatives:

On the left the reworked existing heater block and nozzle just with a standard RepRap nozzle tip

On the right 2 simplified blocks

The magenta surfaces represent M3 threads to easily adjust the nozzle in its hight.

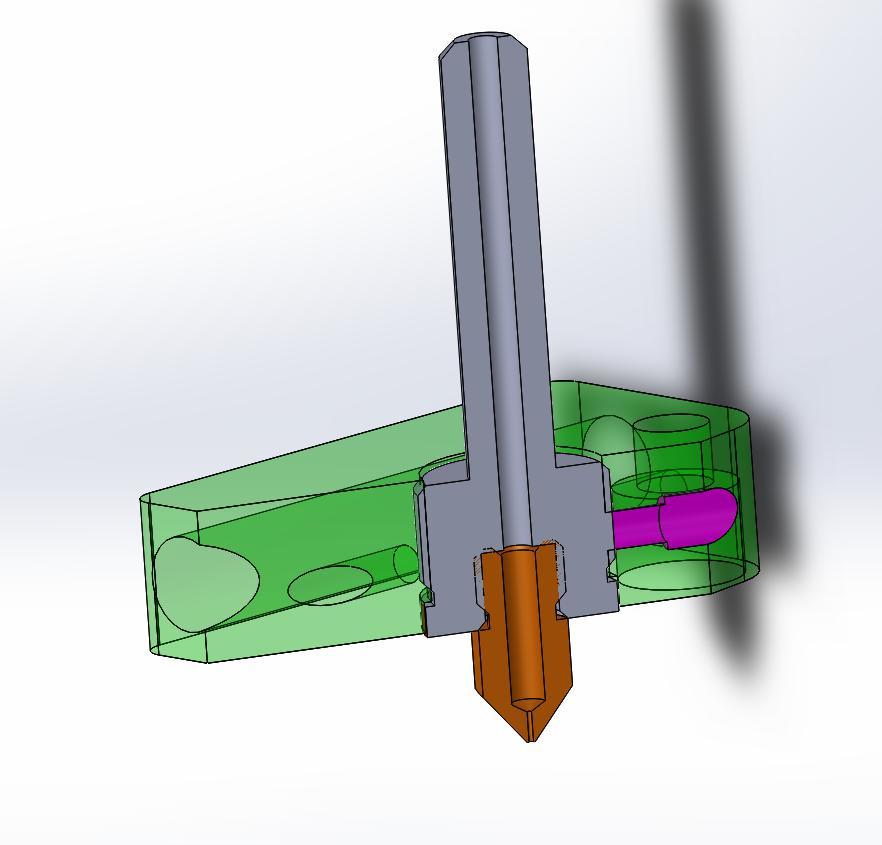

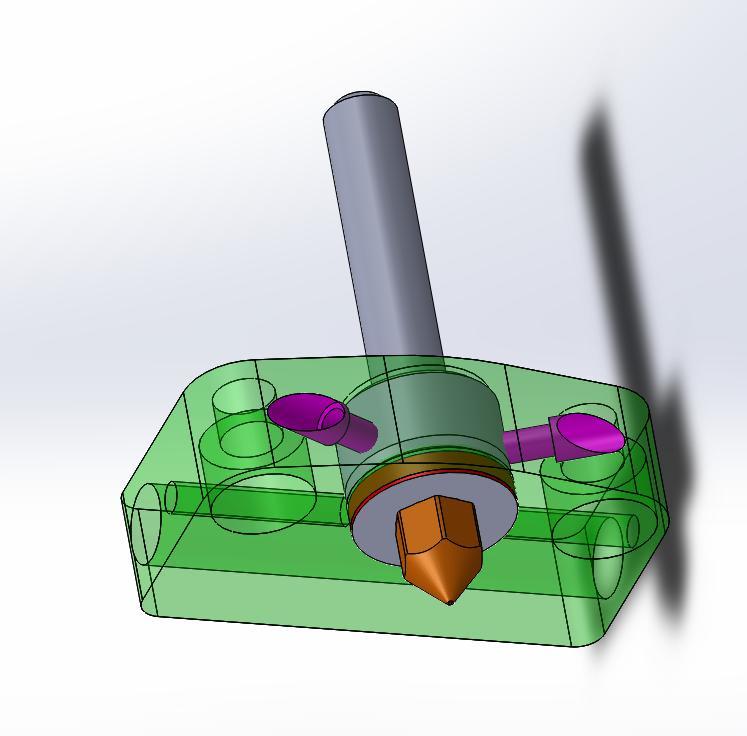

Here the reworked version:

When the red diameter is reduced slightly there is no press fit anymore - then you can use ONE of those magenta threads to block your nozzle and easily adjust its hight.

Also a standard RepRap nozzle is installed (M6 thread) in the standard ZIM nozzle.

…and another picture of it…

( By the way: it’s an BSB 1/2" 26 teeth/inch thread in the heater block - took me several time to find the correct fancy thread… )

My initial thoughts were to make a bushing that would adapt the zim heat block to a std. Rep Rap type nozzle but I shelved that idea due to the fact that we still wouldn’t have a way to replace the heat blocks themselves.

I wish I had an answer to why Zeepro did some of the things they did. That thread in the heat block is a perfect example. A 12mm X 1 would have worked just as well and provided a similar functionality. I’m guessing they wanted a fine adjustment on the nozzle height which is why they went with such a fine thread, but that fine thread is part of the reason these nozzles are so impossible to remove after they’ve been heated up with filament a few times. A courser thread would have been considerably less trouble.

I’ve been testing these things for a few days now and I’m happy to say that they are functioning better than I had hoped for.

They added this BSB 1/2" 26 teeth/inch thread because the brass nozzle is simply created of a standard brass piece you can find at plumber stores. I never understood this too as there are well working nozzles out there with an M6 thread but as far as I have seen now you can remove the nozzle-thing on our ZIM brass pieces and put a M6 into it.

Guys, I need a guinea pig  . I need someone who has experience disassembling the hot ends with knowledge of the Zim feed system to test one of these for me. You’ll need to know how to solder, I don’t have the plug ends for the cartridge heater yet, so you’ll have to solder one of yours on there. If ur interested, email me zim3d@outlook.com.

. I need someone who has experience disassembling the hot ends with knowledge of the Zim feed system to test one of these for me. You’ll need to know how to solder, I don’t have the plug ends for the cartridge heater yet, so you’ll have to solder one of yours on there. If ur interested, email me zim3d@outlook.com.

Any updates on the hot ends?

@winstondon has bravely volunteered to test one out for me. I’m just awaiting his results to confirm that they are working as well on his machine as they do on mine. If everything goes well I should be able to make them available by the end of the week.

Hey guys! ya, I was the lucky winner  . Insomnia’s custom hot end arrived Monday, I just put it up. here are some pictures.

. Insomnia’s custom hot end arrived Monday, I just put it up. here are some pictures.

Haven’t have much time to put some mileage from it at the moment,

Instruction from Insomnia, and pictures

“First, you’ll have to clip the connector off the old hot end on the Zim and solder it to the new one. Polarity is not important so don’t worry what wire goes where on this part. Make sure the wire length is correct. You don’t want to clip it too short. I put a few pieces of shrink wrap on the wires for you. Solder the wires together and melt the shrink wrap around them.”

The heat block it a bit different than the original. The nozzle and throat are 2 separate pieces and are both removable. You’ll receive the hot end with the nozzle and throat loose. This will make it easier for you to adjust the nozzle height. Adjusting the nozzle height is a 2 step process. First, install the hot end and fine tune the nozzle height by threading it out until it’s at your level. Next, take the hot end back out and screw the throat down to meet the nozzle. Last, use a wrench to tighten the nozzle against the throat. This last part is VERY important. if the nozzle is not tight to the throat, you’re going to get oozing from around the outside of the nozzle between the threads."

The assembly.

Good stuff coming out

This is the finished part fresh out of the new hot end!

Insomina made it ultra simple to replace his custom hot end and nozzle, so far so good!

Definitely a light in the dark tunnel for those of us that are worrying the future of our machines.

Thank you Insomina!

That looks very good thank you Winstondon and Insomina.

Awesome guys, great write up Winston, great design Insomnia!

Hi all,

Just getting back into using my Zim after leaving it sit idle for 2 months. I see that zee pro is dead. I just received my heat plate/enclosure recently too. I’d be interested in some custom hot ends. I’m in the middle of disassembling my zim to get to my usb port to try and remove the plug. My plan is to use Simplify3d. Anyone else using this? I may consider octopi or repetier-host as well.

My printers aren’t near a computer, so I use Simplify3d to slice and octopi to print over my network. Works great! I like having the printer status and time lapse video available from anywhere.

jpod, Can you go into a few details of your setup? Are you re-using only the right circuit board in the zim? Do you generate the gcode out of simplify3d and send it wirelessly to the octopi? are you using the zim included wifi dongle or did you get a different one?

@dex0008 I setup a couple of profiles for left and right extruder. Then slice using the appropriate profile and export to a gcode file. Import this gcode into octopi and print. I’ve posted details of this setup previously in the octopi tutorial post.

I found another place you can get these based on the part number.

http://www.digikey.com/product-search/en?keywords=0436450200%20

There only $0.34 so not to bad probably going to pay more in shipping.

When you get the bugs worked out let us know I would be interested in a spare hot end incase one of mine fails.

Bring them on!! Briliant work!! Congrats! Keep us in the loop!

The Hot Ends Just went Live! www.3dprintermods.com. The first ones will ship out on Monday. If you have any questions or concerns, or need assistance with your replacement please feel free to post them here, or email me at zim3d@outlook.com. There are installation instructions available for download on the product pages.

A couple quick notes about these Hot Ends. Most importantly, the nozzles are easily replaceable with standard 6mm nozzles. They feature an all metal throat piece with a Teflon Liner. The Throat piece and the nozzle are both removable and replaceable. While these hot ends are still sided, Right and Left, They can each be used on either side. The only difference between the two is the side which the wires come out of. It’s optimal to have the wires come out the back side, but they are long enough to reverse in a pinch. I still recommend you buy a Right for the Right and a Left for the Left, but this way, if you only have one spare and it’s the wrong side, you can still use it. The only down side to this is there’s a bit of extra wire to have to deal with, but if you tuck it in there carefully everything will fit fine.

Last, These hot ends are complete, there is no soldering required. They come complete with connectors. (thanks to winstondon for identifying them and testing the hot ends for me) You only need an Allen wrench and the screws and spacers off the old ones.

Very nice. Ordered a L and R. One less piece of the Zim I need to worry about failing on me.

Thanks Insomnia !

I would like to get both but there is no internatinal shipping (I’m in France)