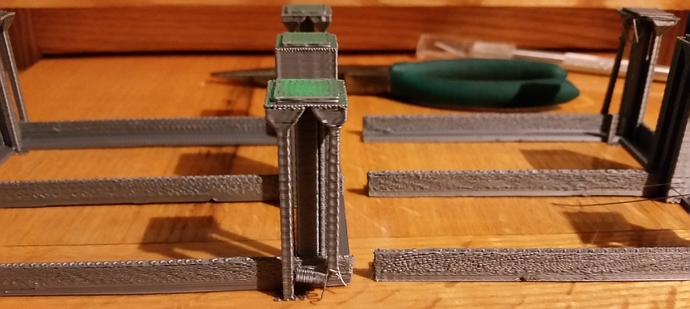

I’m not sure why all of a sudden I’m getting prints that have really thin layers. I thought it might be just not enough layers so increased top and bottom layers to 5 which helped a little bit but still not great. You can see in the picture how the top layer is almost missing in spots. (This print was with the default high quality setting) This isn’t just the top layer sometimes the infill is like that as well and is just missing. Any Idea’s?

Thanks!

I don’t know why different PLA brands have such different temperatures they like.

I don’t know why different PLA brands have such different temperatures they like.