Ive decided to essentially gut out my Zim and yse the materials salvaged from it to make a new printer from scratch.

(Im doing this to my second zim, still love the way my first one is running)

My plan is to use the same controller board servos abd etc. But to redo the frame with pieces of T-slot extruded aluminum. And everything else being 3D printable.

Looking at what zim did on their mechanical side i really really love. If it wasnt for their buisness model and poor Q.C. i think they could have made it a new standard for 3D printing.

(The holding nut in the extruder with the 4 notches should have been made longer with 2 flats for easy wrench tightening.)

Anyways my eventual goal is to make a easily sourced alternate extruder head for everybody with a current zim. With an alternate goal of making a new 3D printer whose parts are more easily sourced.

I plan to use the same design as zeepro used as much as possible, cause i think they were really onto something with it.

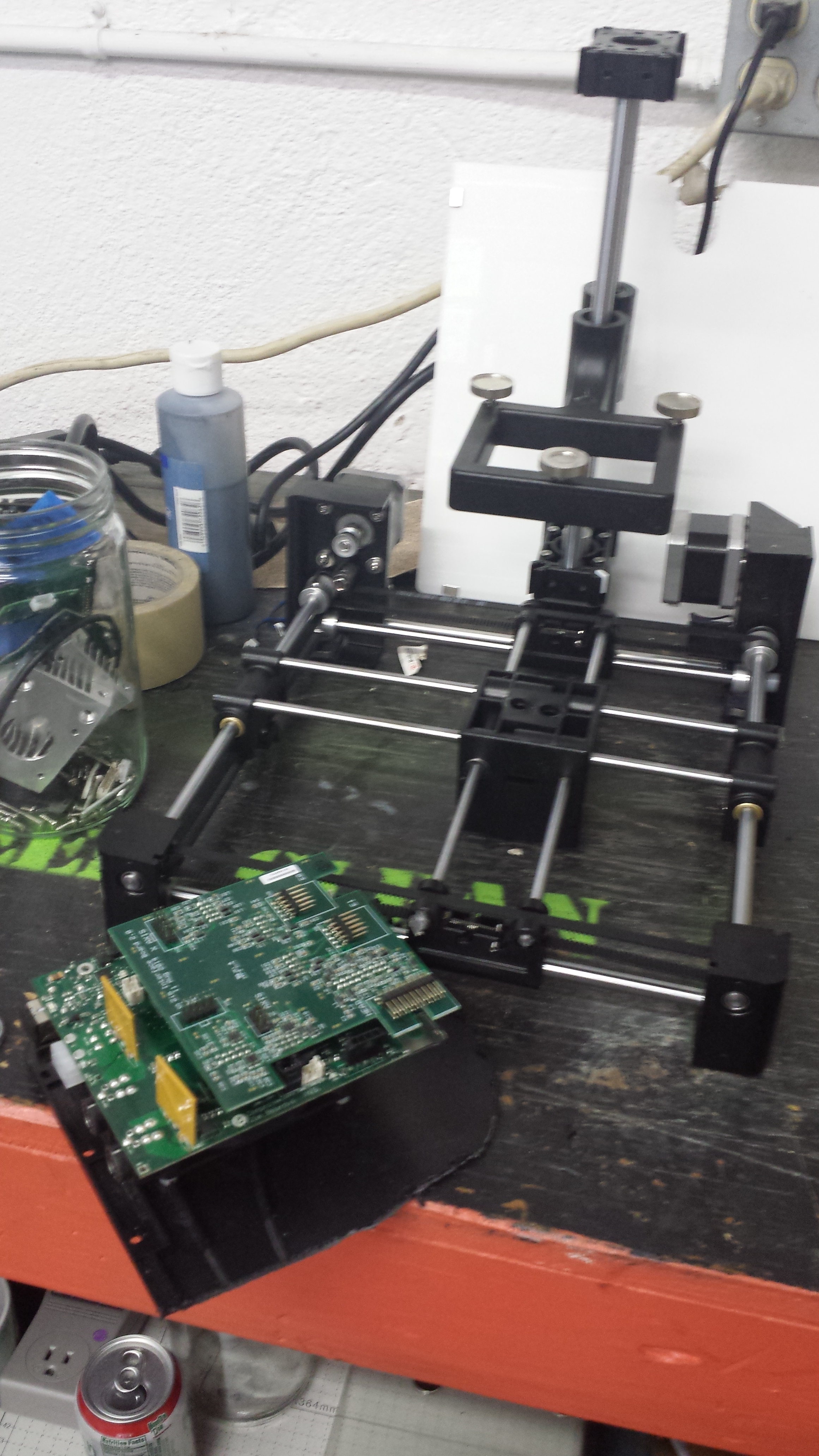

I finished the disassembly today so here is what I have.

I have a write up for most of the connections with the current board. But i messed up the chip on the head. If anybody who is also planning to git their zim like i did. Could either finish the write up or send it to me to finish what ive got itd be appreciated.