I just spent 3+ hours printing something that just needs to be capped off to seal up the very top layer, but it ran out of filament while using OctoPrint. Has anyone attempted this before?

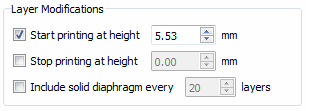

One idea to accomplish this would be to measure the height of the incomplete print on the bed, and figure out where in the GCODE to resume the print more or less. I have no idea how to interpret all of the GCODE yet though. Then edit the GCODE and remove all of the codes at the beginning, manually heat up the extruder and run the GCODE without any other homing or nozzle wipe scripts. The trouble though is if there are any mistakes, the extruder is going to collide with this big part on the bed and probably rip the bed off of it’s magnetic mounts or worse.

It sure would be nice in the future to have the print automatically pause after it detects the filament missing in the lower feeder (there is a microswitch there which I’m assuming is ignored now with octoprint). That way I could notice it, or possibly create a push notification plugin that alerts me that I’m out of filament. Maybe the Zimboard would need to detect this (I’m sure it does already) and send a special Pause command to OctoPrint?