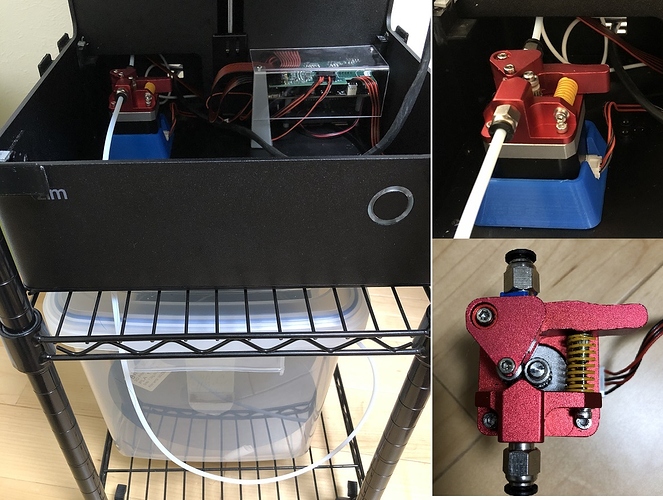

Before I started to try ABS, I made enclosure like following;

White box underneath Zim is filament box with desiccant.

Following red extruder pumps up filament from box.

Power pack and Raspberry Pi are located at backside of Zim.

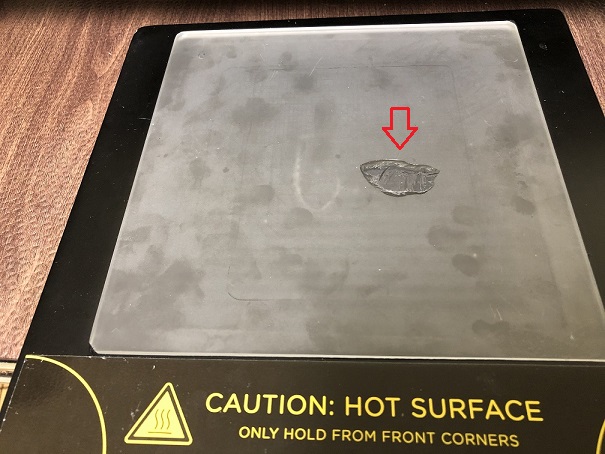

When I was trying to print ABS, the outcome was so terrible.

Problems at that time were, difficult to stick 1st layer on build plate, therefore no choice but to increase temp of heat-bed like 90deg or more.

That high temp of bed caused terrible shrinking from bottom.

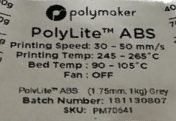

I am using following material.

Not tried another material yet.

Found that using cooling fan (left fan) helped so much otherwise deforming like melting, but the problem was, temp of hot end dropped, lower temp of hot end caused bad adhesive of each layers.

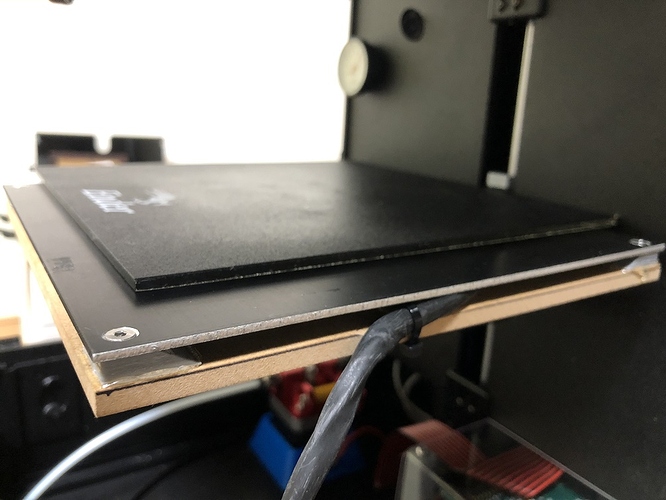

Solution for 1st layer sticking on bed;

Found that hair-spray helped so much.

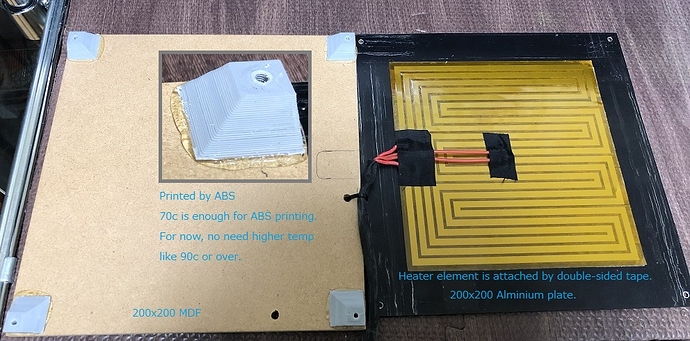

Possible to lower the temp of bed, 70deg is good enough, no shrinking.

Now I am using Ender sheet but it sticks too strong, therefore still I use hair-spray on it.

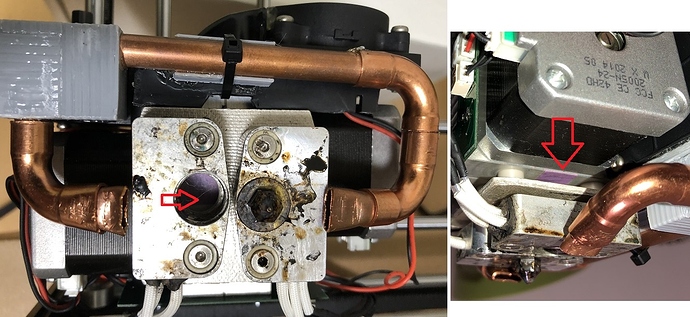

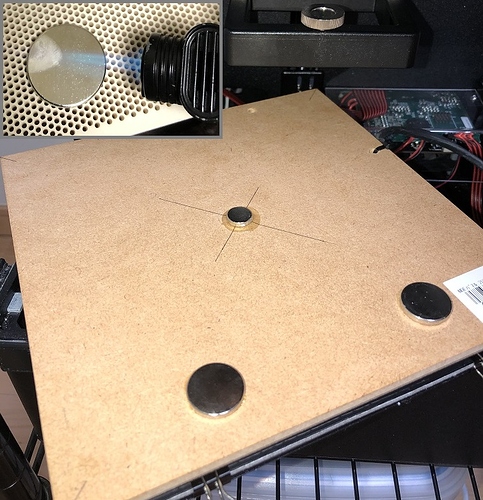

Solution for deforming like melting, improvement for cooling fan.

I used copper pipe for cooling duct.

You see gray disc at intake of left fan, it is orifice to reduce airflow.

Found that un-wanted air flow from heat sink caused dropping temp of hot end.

So I sealed that hole.

You see purple tape on heat sink.

Conclusion of my case is;

Fan speed 25% with orifice works fine !

Nozzle temp 240, bed temp 70 with hair-spray.

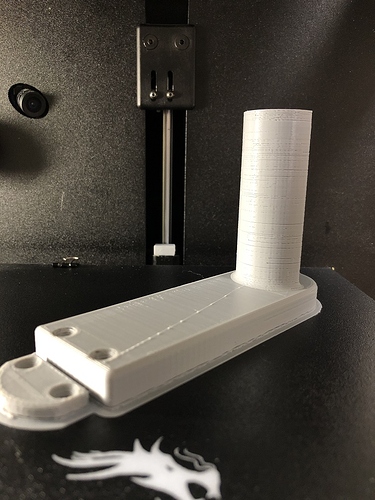

Recently, I printed relatively big object, it is spool holder.

No warping, no crack, no deform !!

Attached inside filament box.

It replaced old holder made from PLA.