I don`t know whether this topic interests someone or not, I will share anyway.

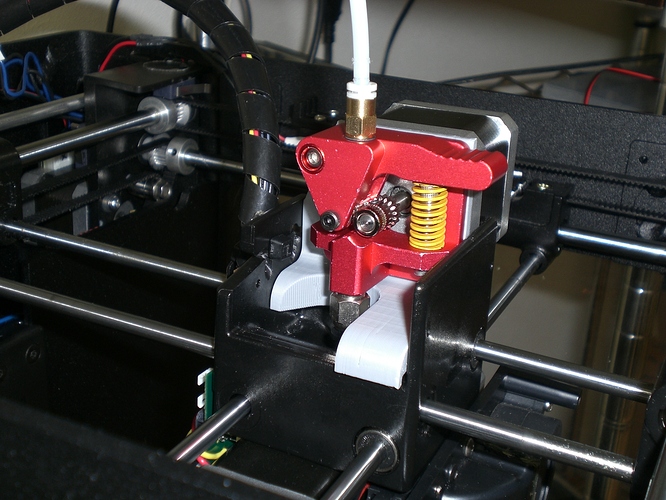

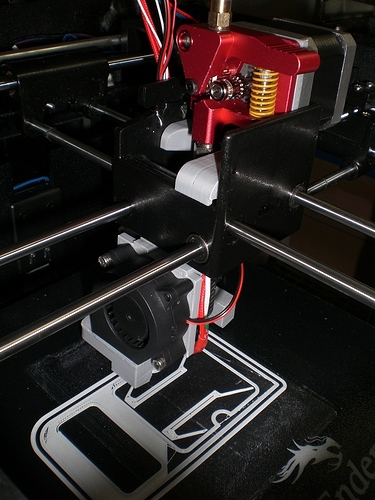

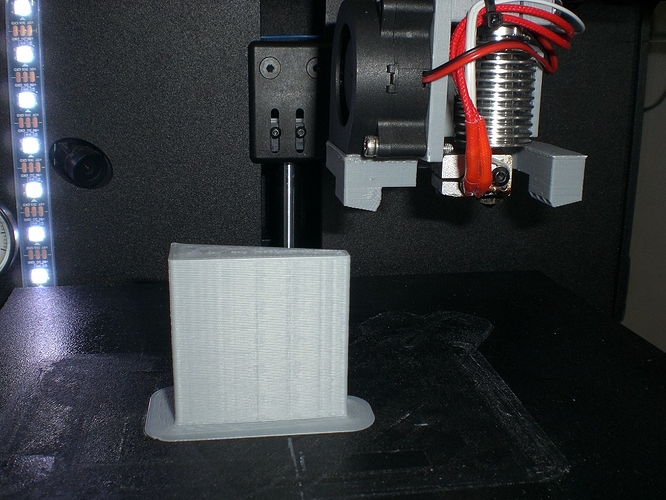

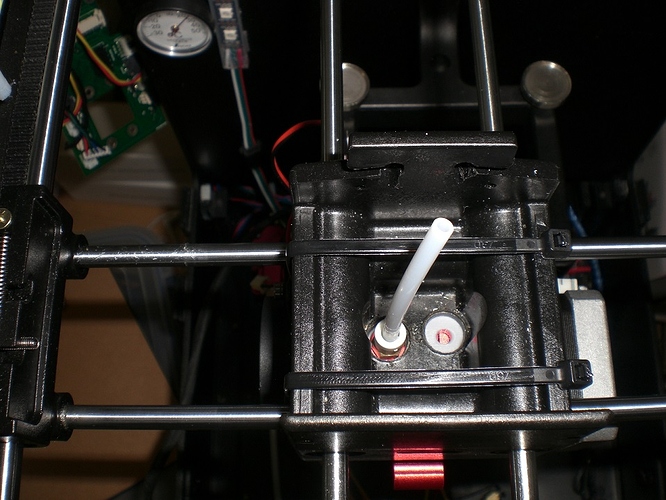

Zim is now become really old machine but mechanics and chassis are really nice I think.

It is worth to upgrade.

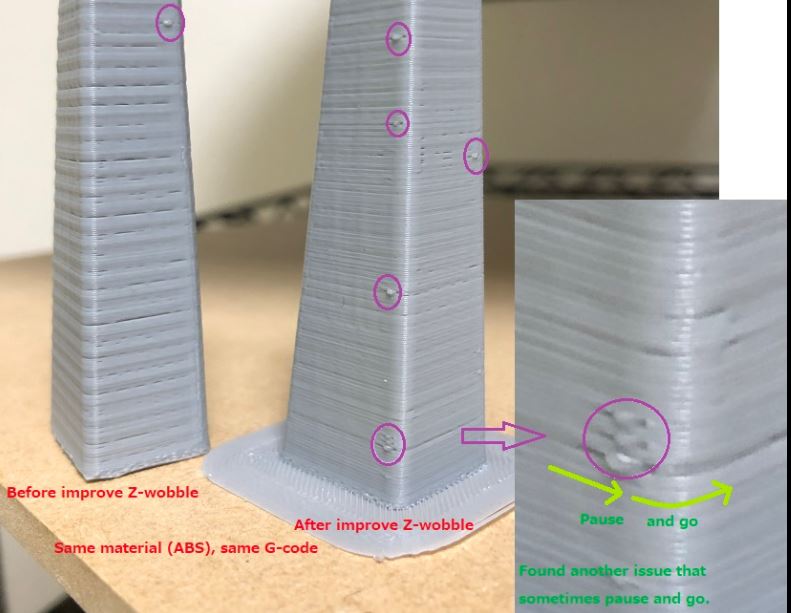

Main reason for upgrade is, to solve “pause and go” problem.

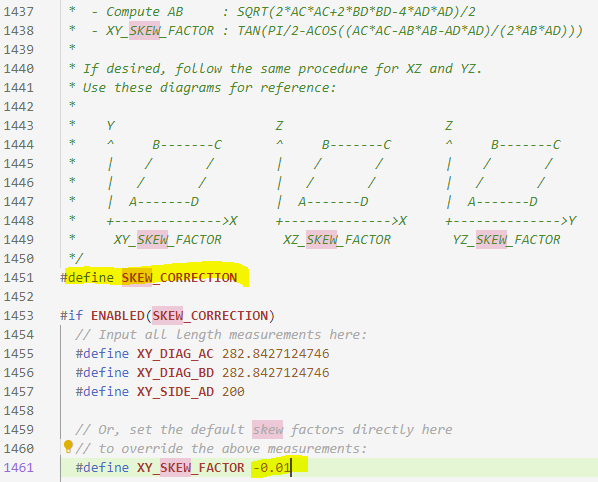

And I wanted to compensate skew (backslash) too.

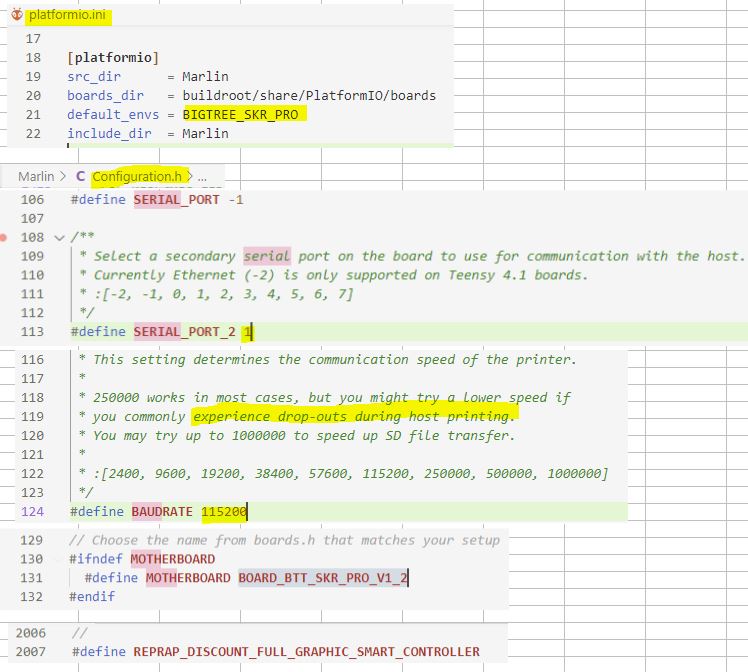

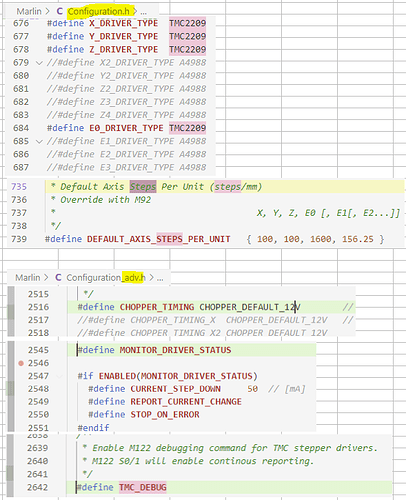

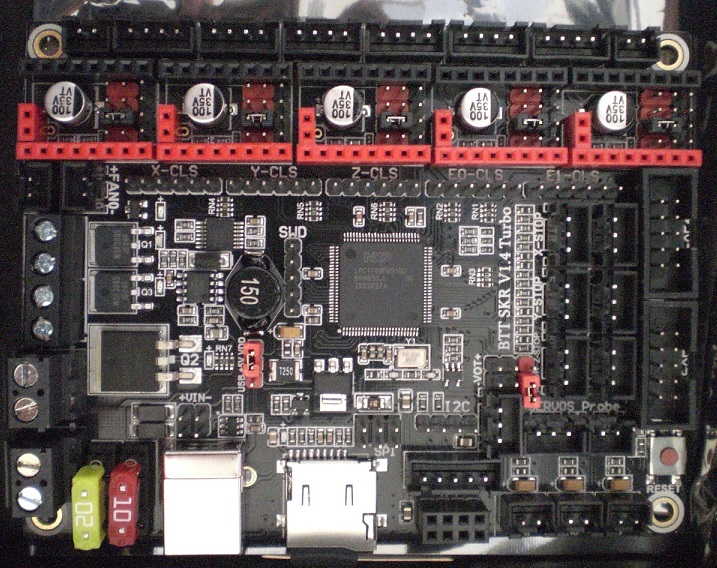

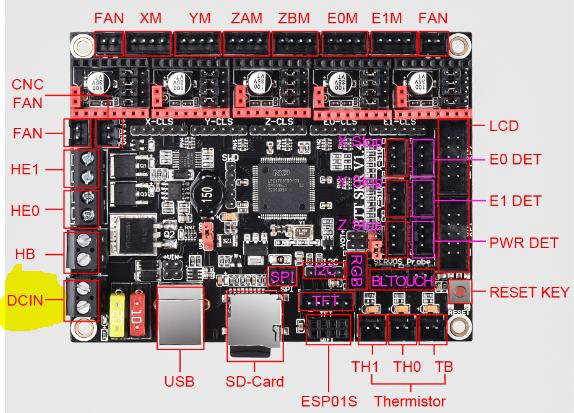

I choose Big tree tech SKR Pro V1.2 + TMC2209

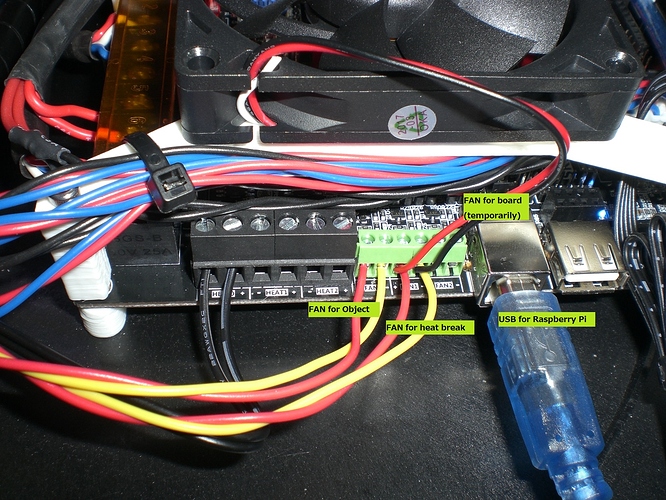

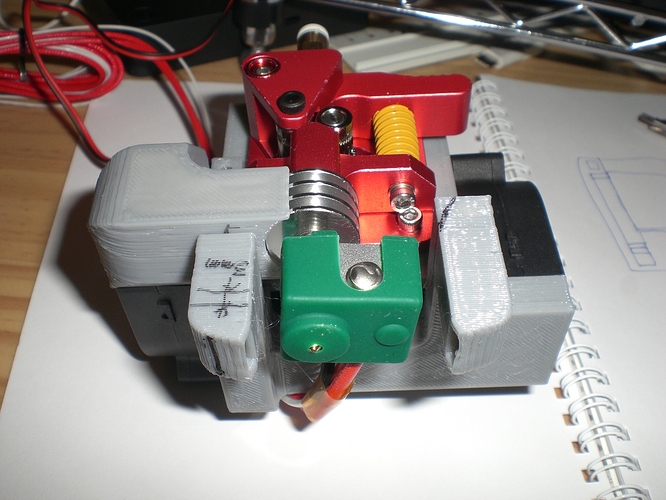

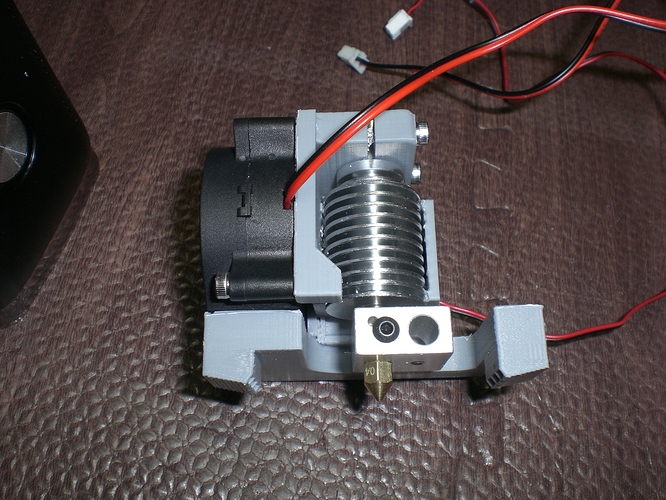

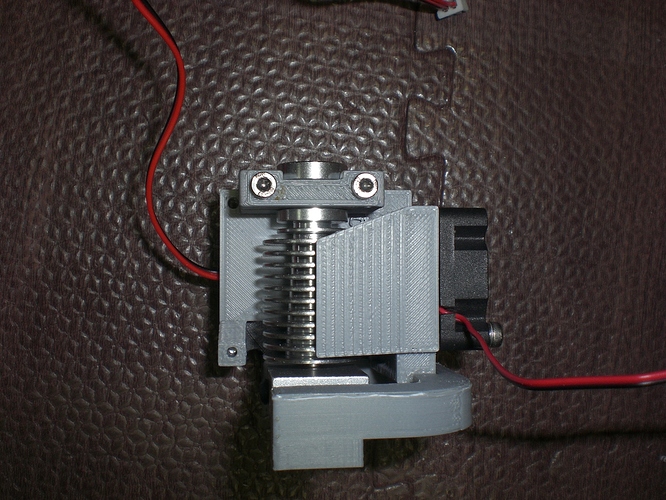

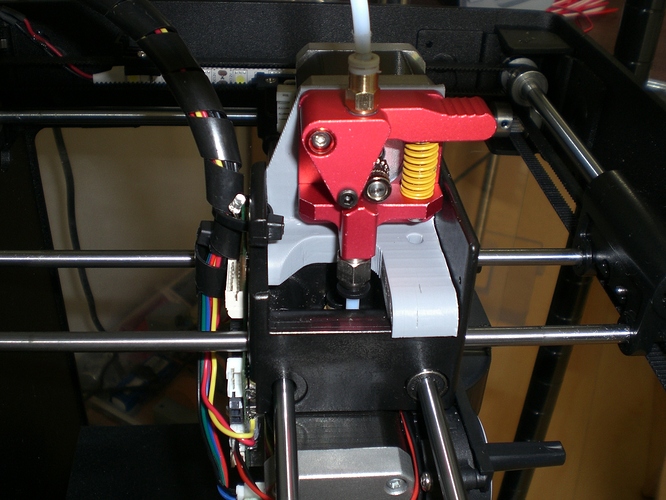

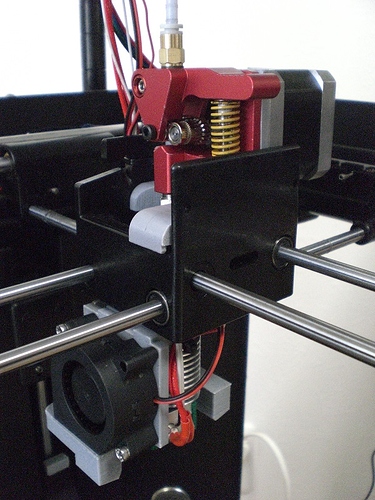

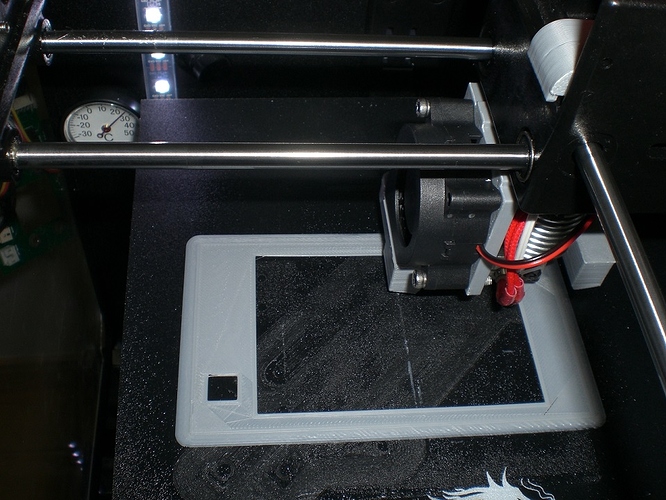

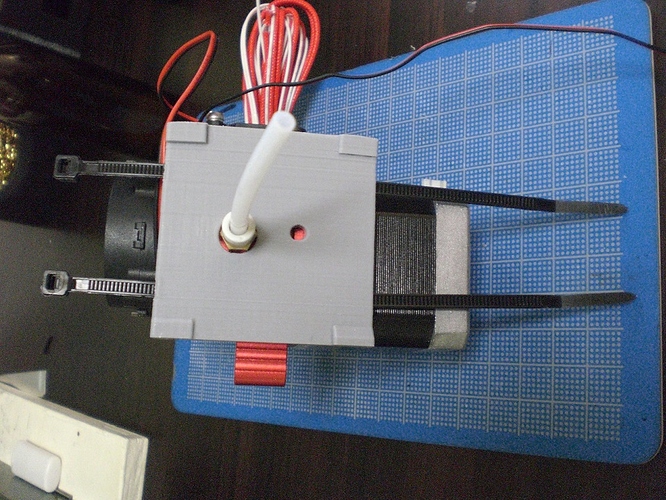

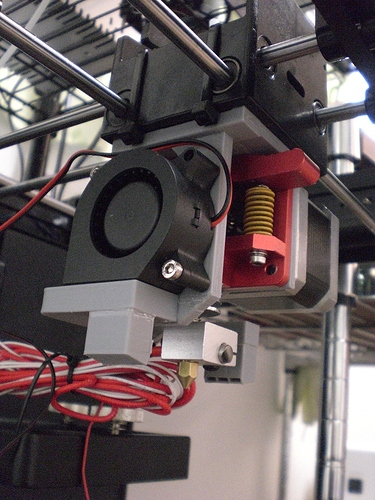

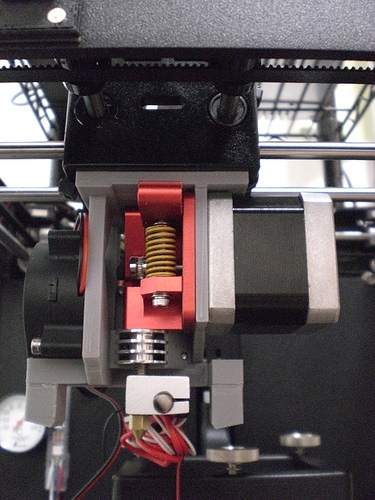

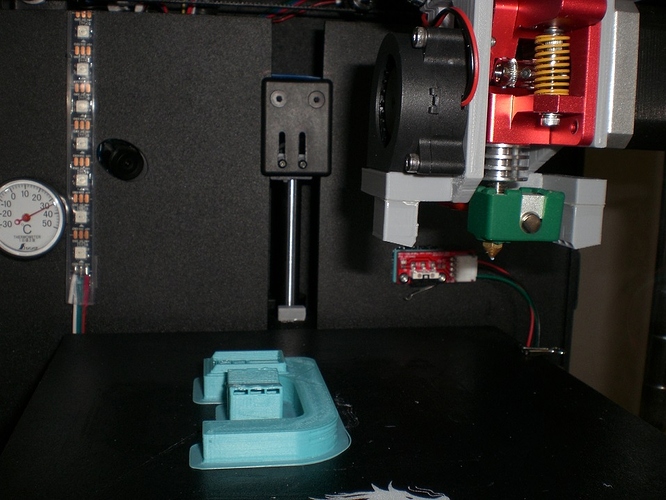

Now it looks like this.

Possible to operate via LCD touch panel.

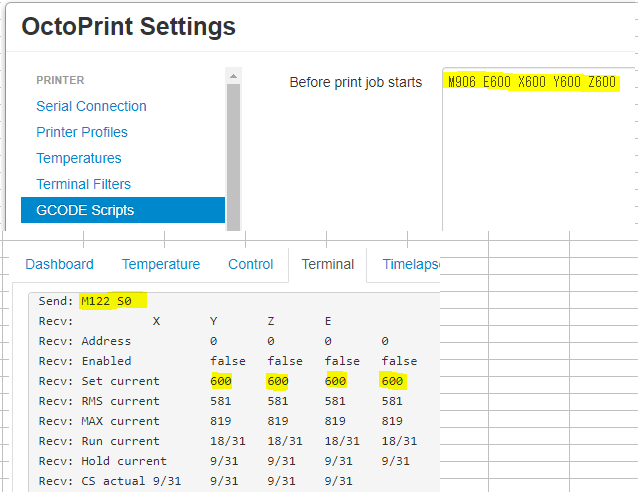

Oct Print is also available, Raspberry Pi is connected via USB.

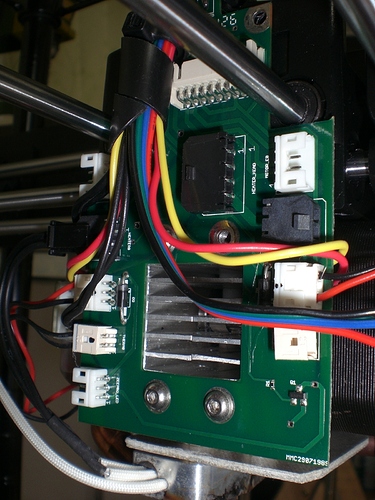

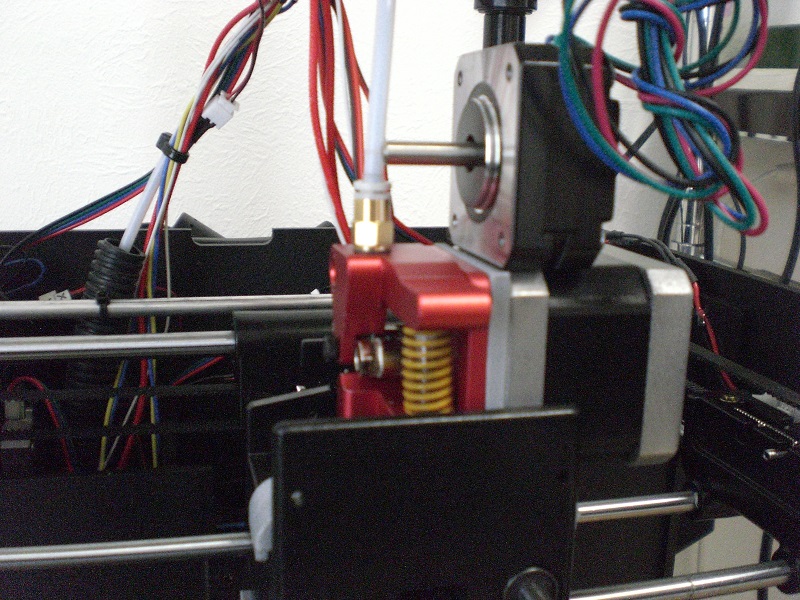

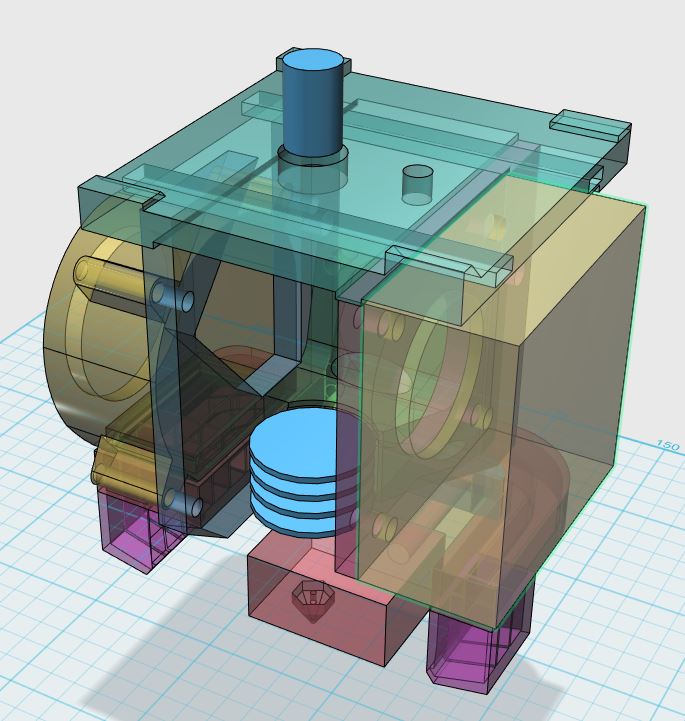

Soldered wires behind connection board at head.

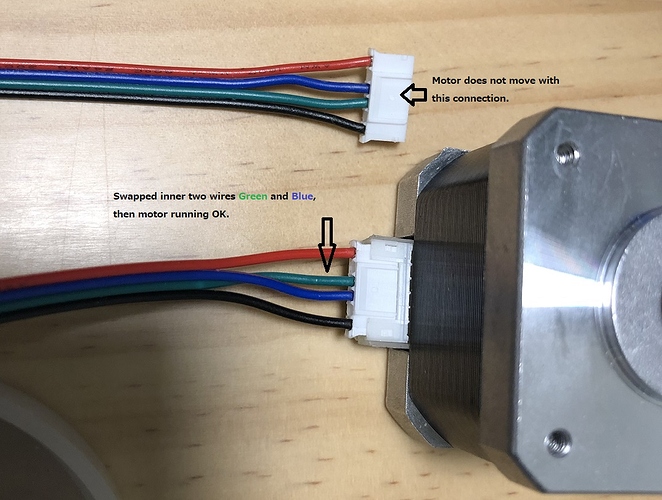

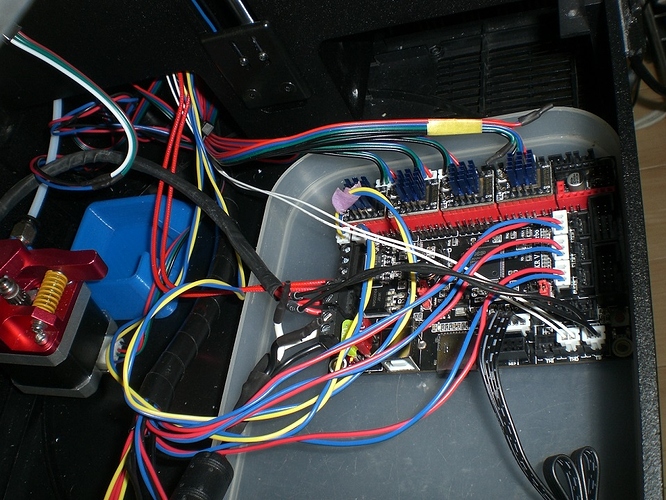

Before install new board, tested to drive stepper motors and limit switches.

In the beginning, motor would not rotate at all.

Found that motor cable was wrongly connected.

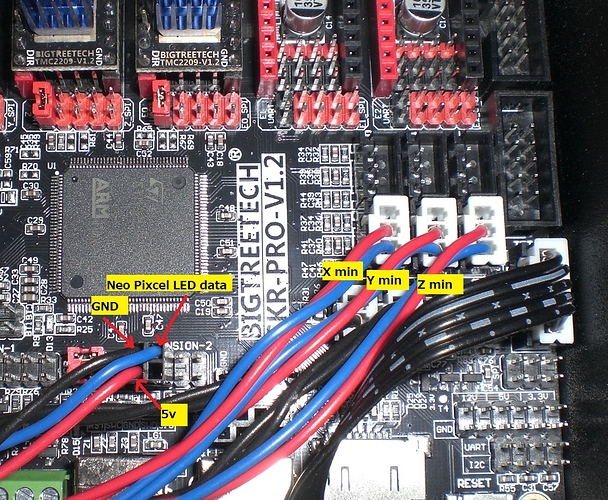

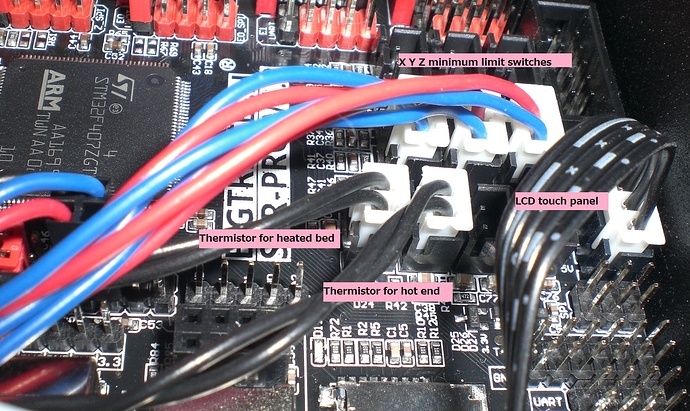

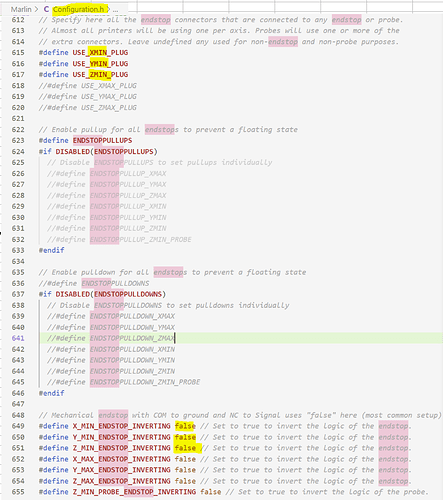

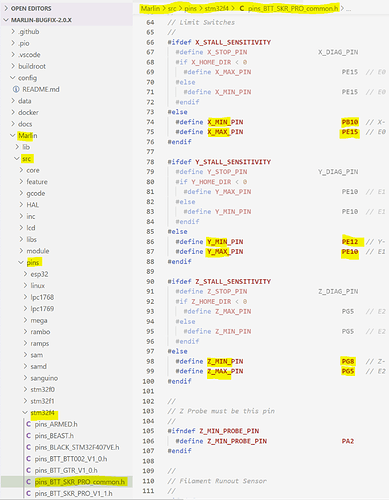

I was confused about limit switches.

Seems Zim has NC (normal closed) switches.

Finally, connected like following.

Red wires for limit switches are for GND, so I should have used black wires…

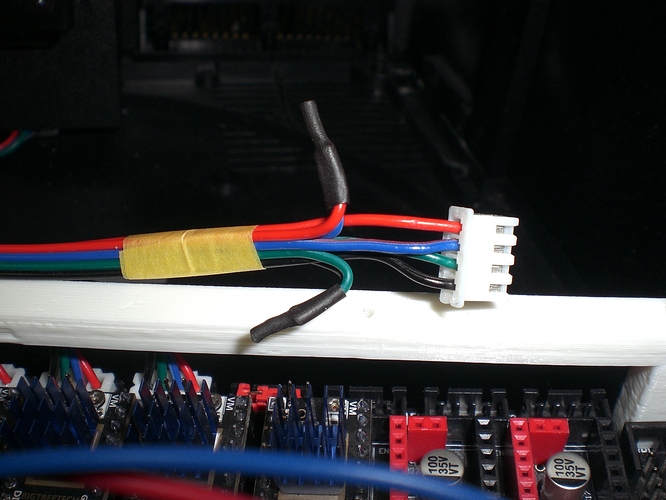

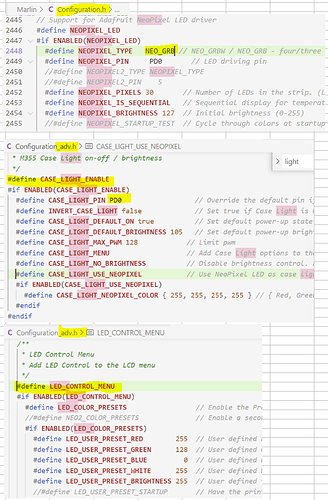

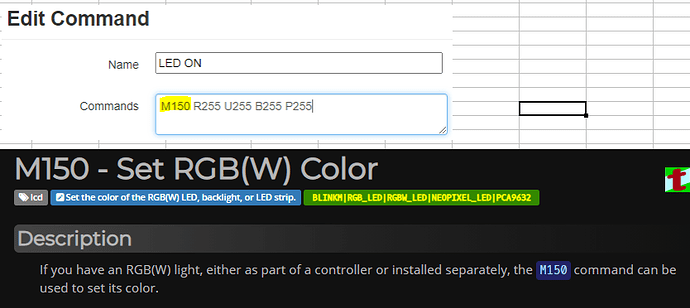

Connected Neo Pixel LED for chamber light like above.

I use RGB, possible to select RGBW.

I will mention about LED later.

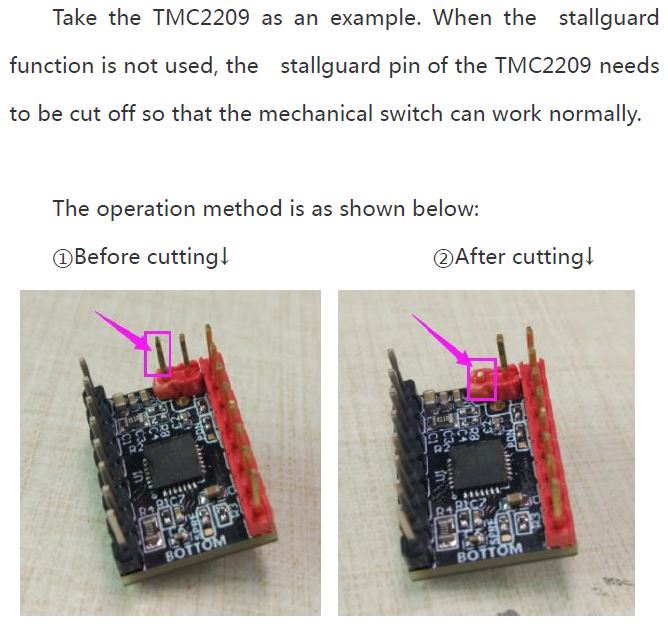

In the beginning, limit sensor did not work at all.

Found that needed to cut one pin at motor driver TMC2209.

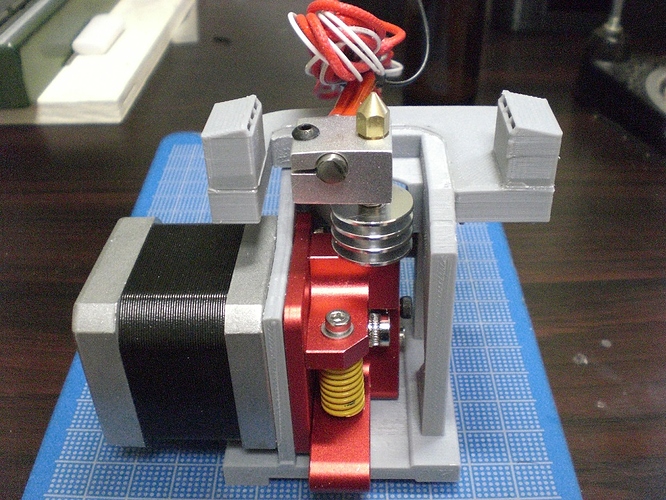

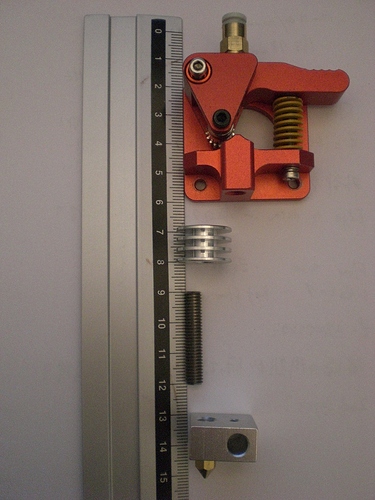

I use two stepper motors for one nozzle, therefore need to connect two motors in series.

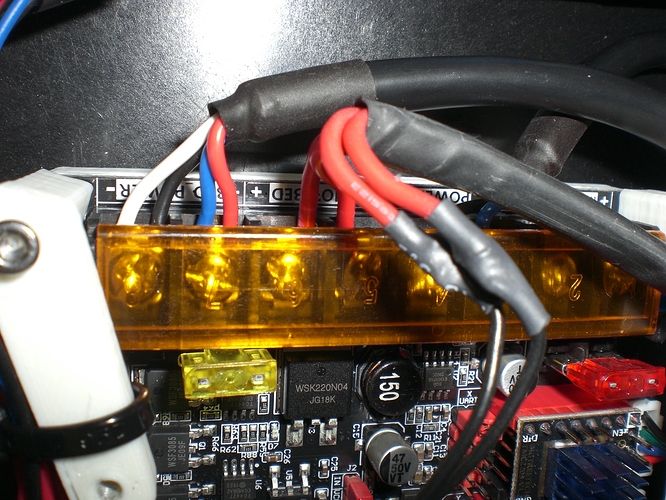

12v power connection for board and motors (and hot end).

12v power connection for heated bed.

Thermistors.

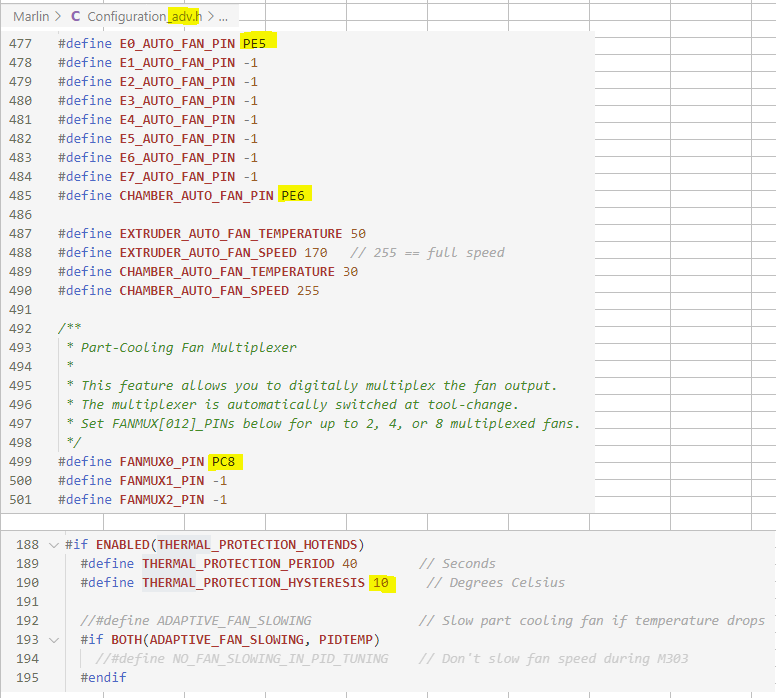

FANs.

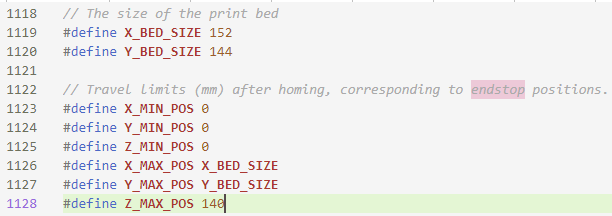

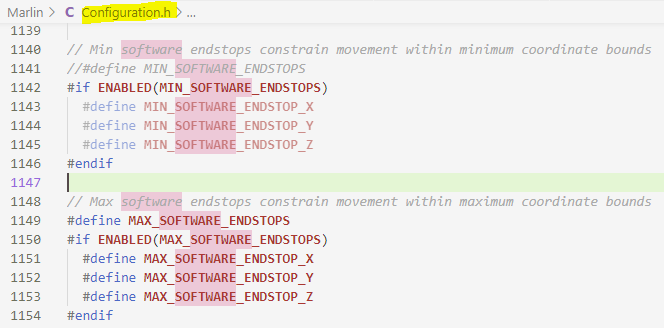

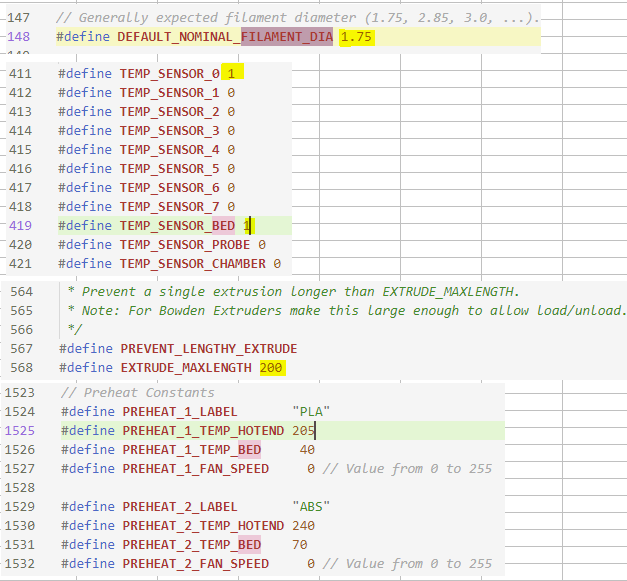

I will continue more about Marlin FW setup later on.