Dear Friends,

Bfore someone says “go read the read the forum”…I´ve most of it. My USB por was dead…Now its working. I´ve bought a PI and tried my best to follow the instruction…Frustration took over since i recently moved and theres not a SINGLE usd to USB cable on this bloody house…Moving on…After reading everything and since clearly patience is not one of my virtues. I need someone to please just answer a simple question:

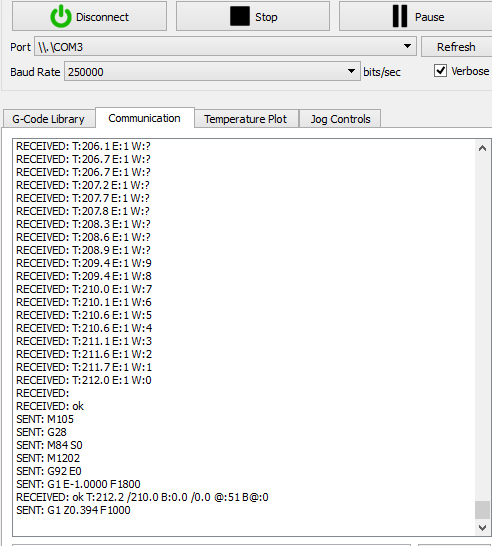

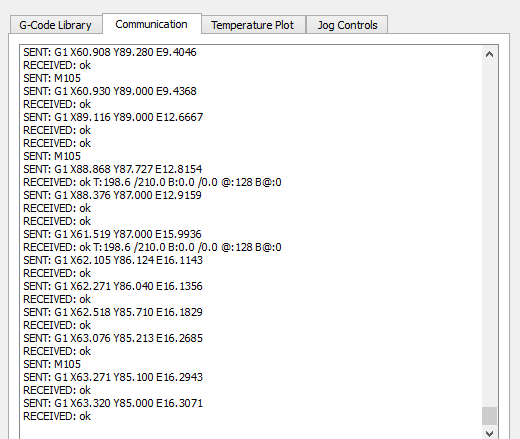

-> Can i use the Zim, connected directly via USB to the computer (not using RPI, or Octopi), and SIMPLIFY 3D?

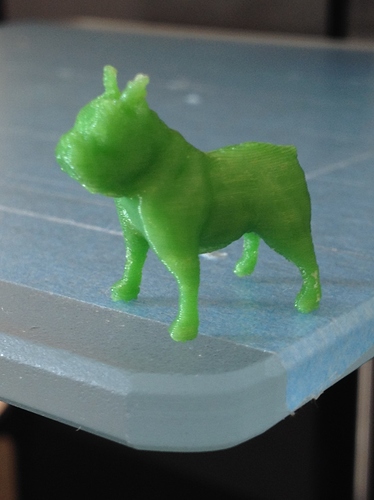

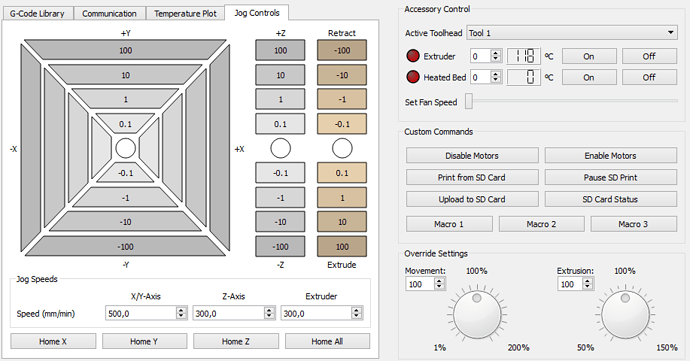

Honestly i have everything (hardware) but im interested im spending my time designing and printing objects. The set up for me must be basic. To my understanding there is no need to use a PI if you dont want a camera, or a wifi connection to the printer. I removed the A10 Board since i guess is not needed for USB connection with this setup. So, why the hell cant i seem to be able to extrude anything from each nozzle after heating them up to 250C (PLA)?

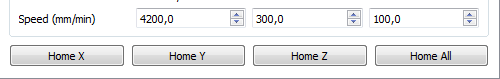

What is the extruder speed you gyus are using:

Is there any known problem with SIMPLIFY3d Direct USB connection?

Thanks and sorry but i spent the WHOLE afternoon dismounting ZIM, and mounting ZIM, and 6 hours later i Still cant print anything…

Hope you work out your issues!

Hope you work out your issues!