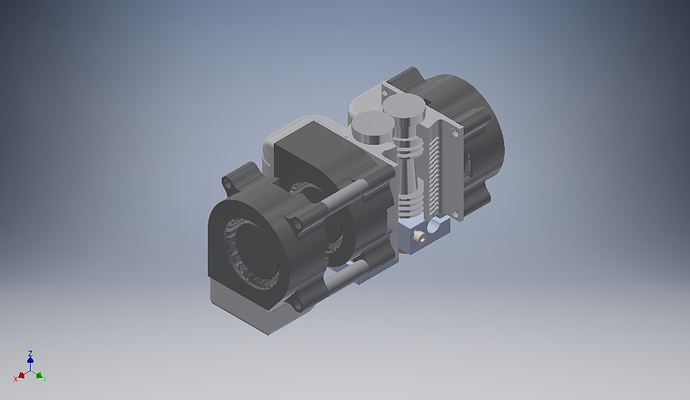

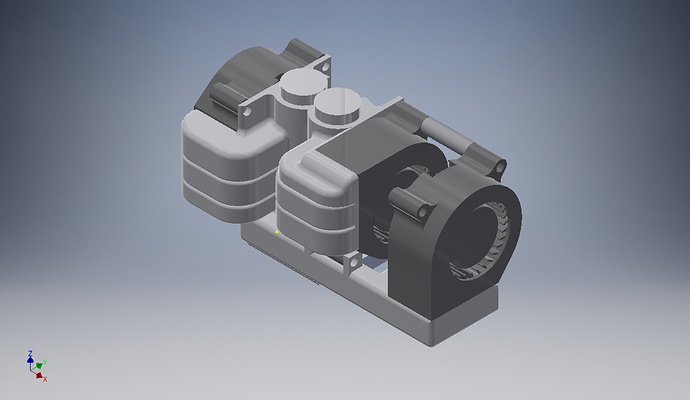

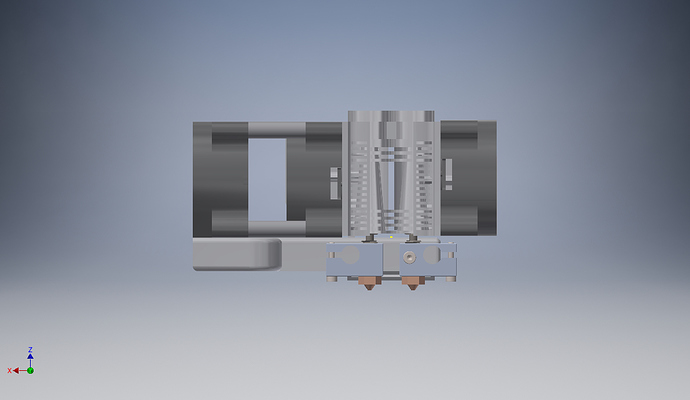

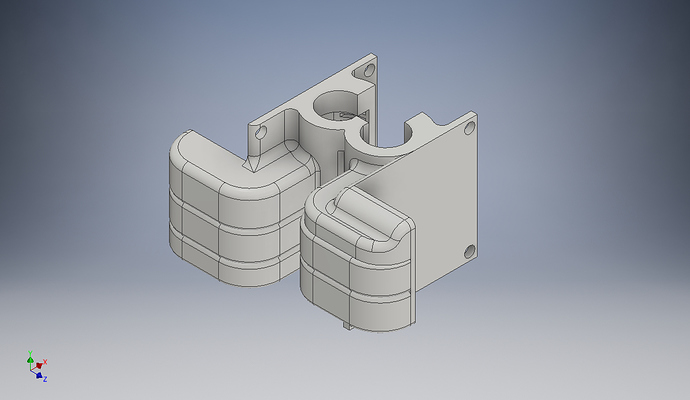

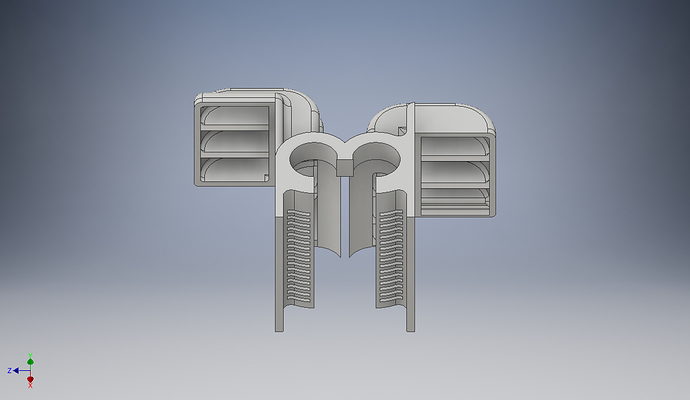

Building on what some users are doing, adding an E3D or an E3D v6 clone, I machined down an e3D and designed a custom mount that will fit directly on to the Zim carriage. I haven’t printed this out yet because I am also wiring a new RAMPS board into my printer, but I’ll get a copy printed off tomorrow at school, I’ll upload the files on thingiverse once It is a complete project, but I just wanted to let people know it was being worked at.

NOTE:I am aware that E3D V6’s don’t reach all the way down to the build platform, and quite by mistake I found that lamp repair brass tubes and fittings fit perfectly to fix this issue. I used this:

UPDATE #1 2/23/17

Tolerances were too tight and I snapped the piece. I’ll get another printed off:

UPDATE #2 2/24/17

I got another part printed off and I left it at school to get the supports dissolved:

UPDATE #3 3/11/17

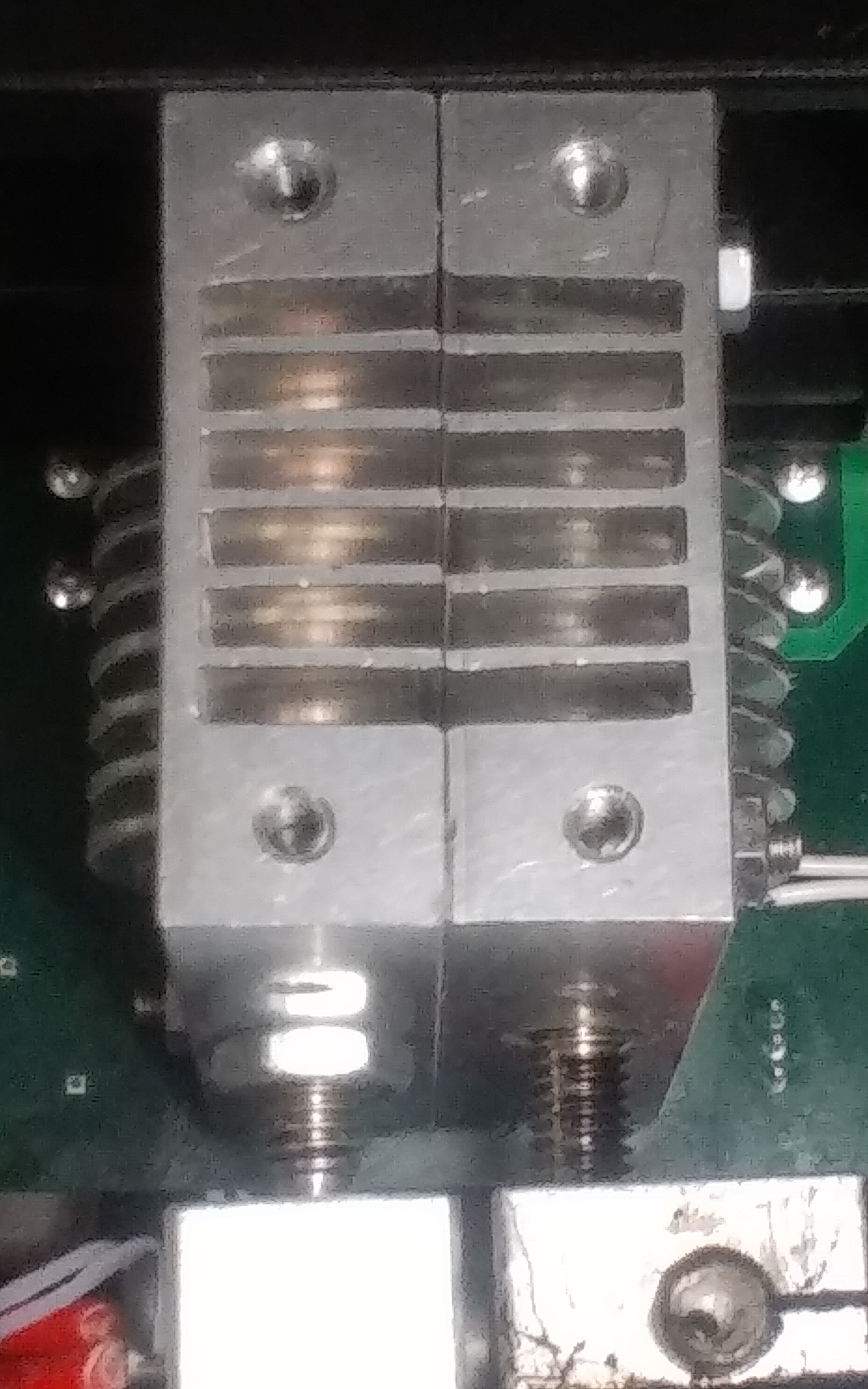

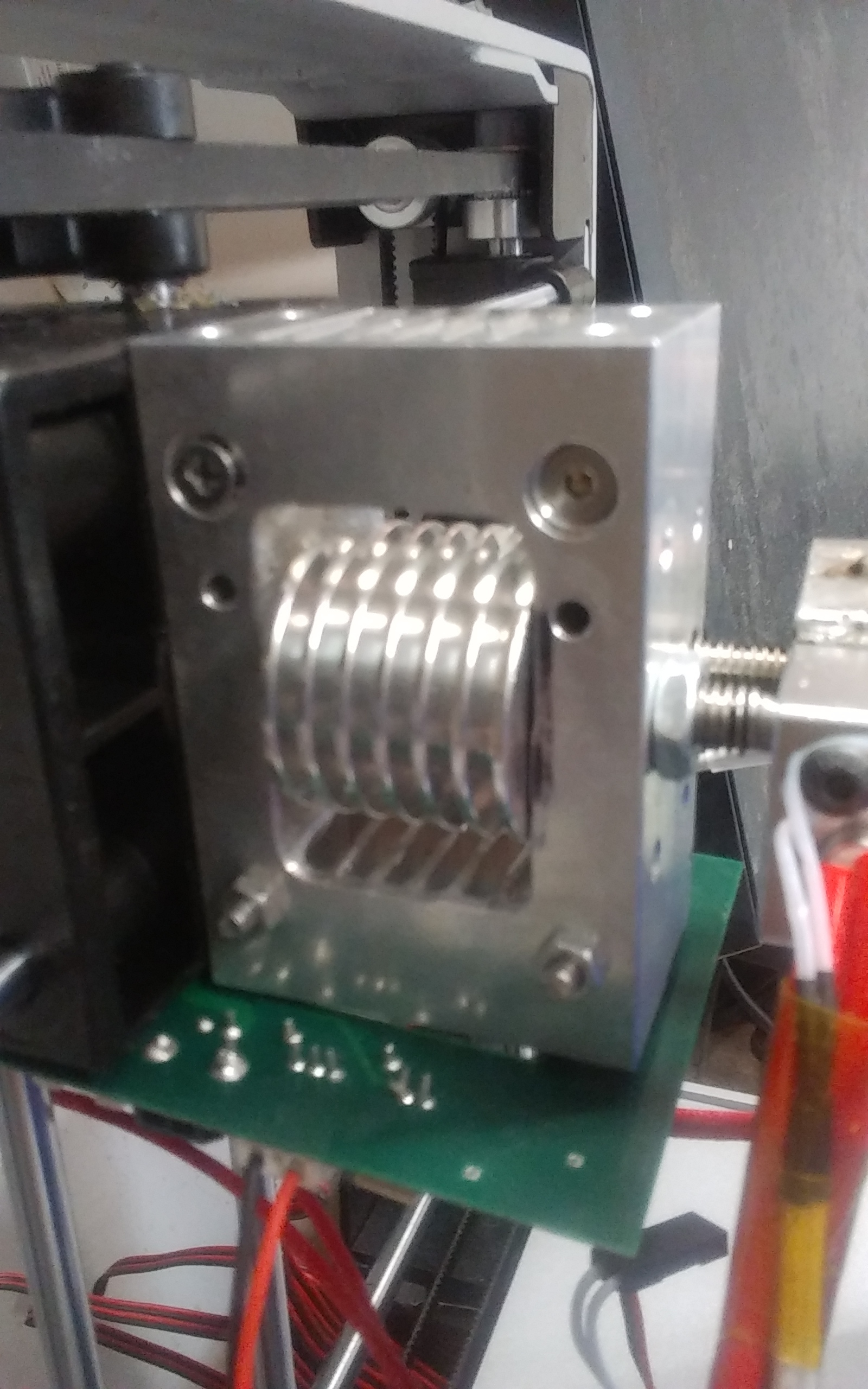

Still waiting for my heater cartridges to arrive, but some bowden Extruders came in the mail yesterday. I installed them on the back of my Zim:

Thingiverse download link: Zim custom extruder

When I get the heater cartridges I ordered I’ll make an in depth tutorial on how to put all this together.