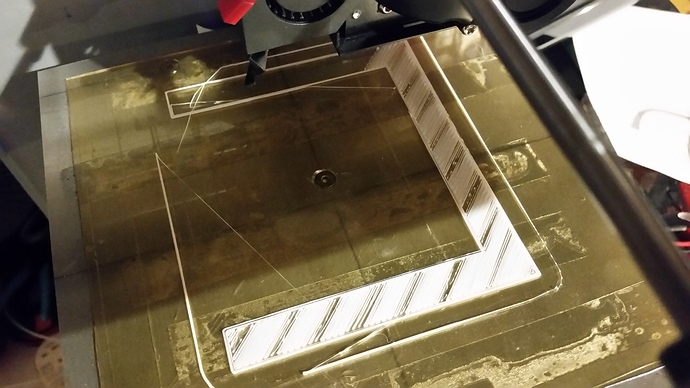

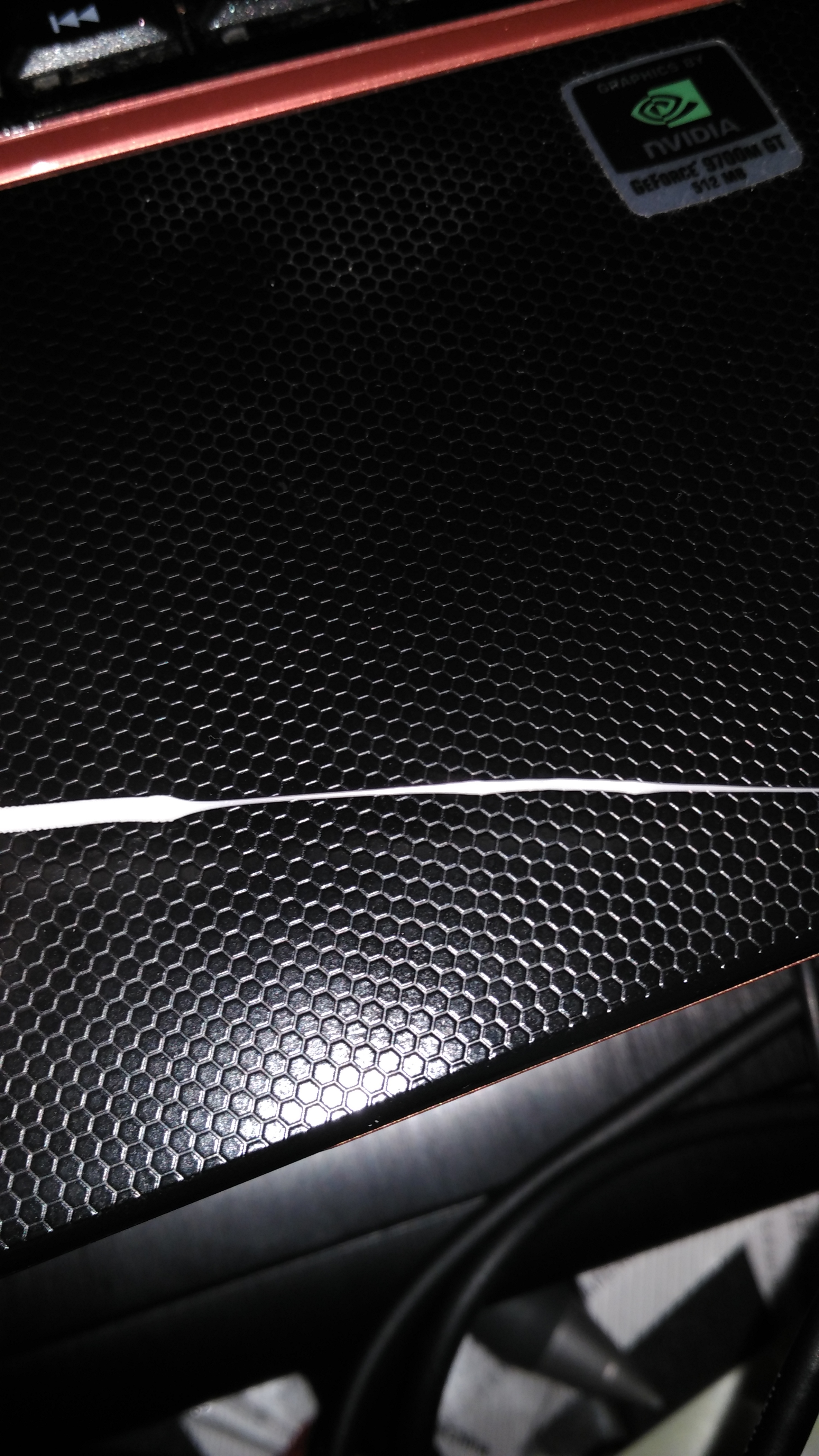

So I switched to PETG to try and print some large parts that can have water on them for long periods with out degradation. However I haven’t been having much luck. I printed some small parts and it was fine then switched to a large print and can’t get it to work. It acts like the printer is varying the speed that it is extruding the plastic since some area’s don’t have enough plastic other area’s are fine. See picture below. Also the stripes are in different spots but are spaced the same in all of the prints I have tried. Any one have any suggestions?

Inconsistent filament extrusion

hum… What is your extrusion temperature ?

It looks like the extruder gears are ripping. but the problems is cycling quite regulary.

I would try to ncrease the temperature and reduce the print speed.

(It could also be the spool that is forcing… as it is cycling…)

So I was running the first layer at 225 so I upped the temperature to 230, I also removed the enclosure and pulled some filament off the spool so it was hanging down hoping to make sure it wasnt the spool pulling. I also dropped the first layer speed from 25mm/s to 20mm/s. It looks slightly better but defiantly still have lines. Any other suggestions to try? I’m going to switch back to PLA and try a print with that to see if its the material or the printer.

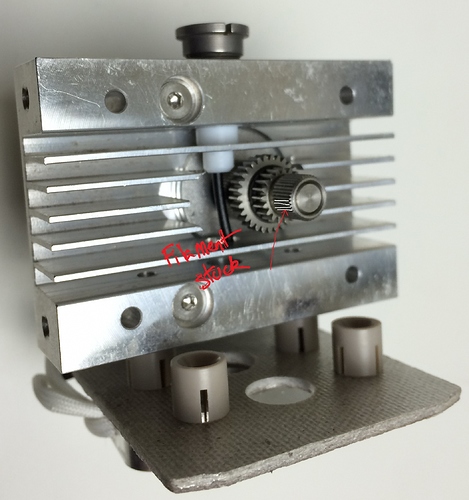

I had same issue once.

I cleaned stepper motors teeth with a needle.

maybe you have same problem.

I fallowed this instructions to disassembly head :

http://zimsupport.zeepro.com/support/solutions/articles/5000049257-how-to-unclog-the-nozzle

or if you have a long needle you could do it without disassembly

Ok, did a print with PLA and the results look identical to the first picture I posted. The temperature was 195 first layer and then 200 for the second half of the first layer and that didn’t make any difference. One thing I did find though is that the printer isn’t pulling the filament in. I held my finger on the filament as it entered the tube and I can feel it pulling and then slow down to a stop in the area’s its not printing.

@eric That is a very good possibility. I will take the head apart this morning and see what the teeth look like. Thanks for the tip.

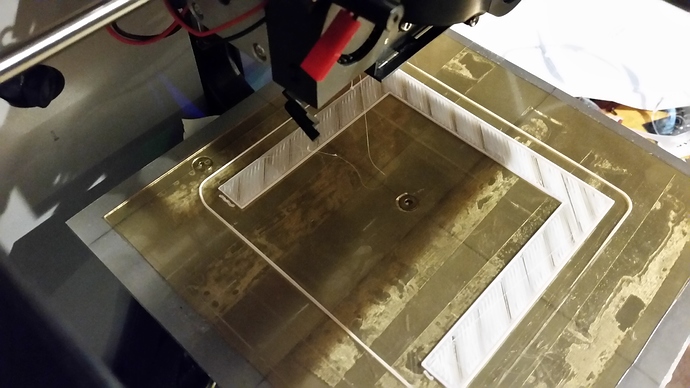

I took the head apart and there was a little bit of plastic in the teeth so I cleaned them up and put it back together. It still has stripes but they are less pronounced than they were so I’m letting the print run to see how it comes out. If anyone has any other idea’s let me know. I checked the the motor seems to be spinning consistently so its not a drive problem.

Have you measured your filament at several positions and in different positions? Just to make sure that it´s round and in tolerance… I once had filament that had 0.2mm variation in diameter because it was oval.

Another possibility would be a lack of pressure on the filament. I described a way to slightly increase the pressure in this post

I will have to take the head apart again and try that. Thanks @J_Schmidt.

I did find some more information on my problem, I’m using the replacement heads and not the original design, one of the replacement heads came with a longer metal stud than the other, and I think the longer stud was conducting heat up the filament and allowing it to warm the filament going through the gear so it was soft. (I installed the metal stud backwards with the plastic tip down so that is my fault) I put one of the short studs in and it works better but still getting some stripes.

How can I ovoid Inconsistent extrusion?

I clean twice teeth on step motors, disassembly head to check inside… I don’t know what to find.

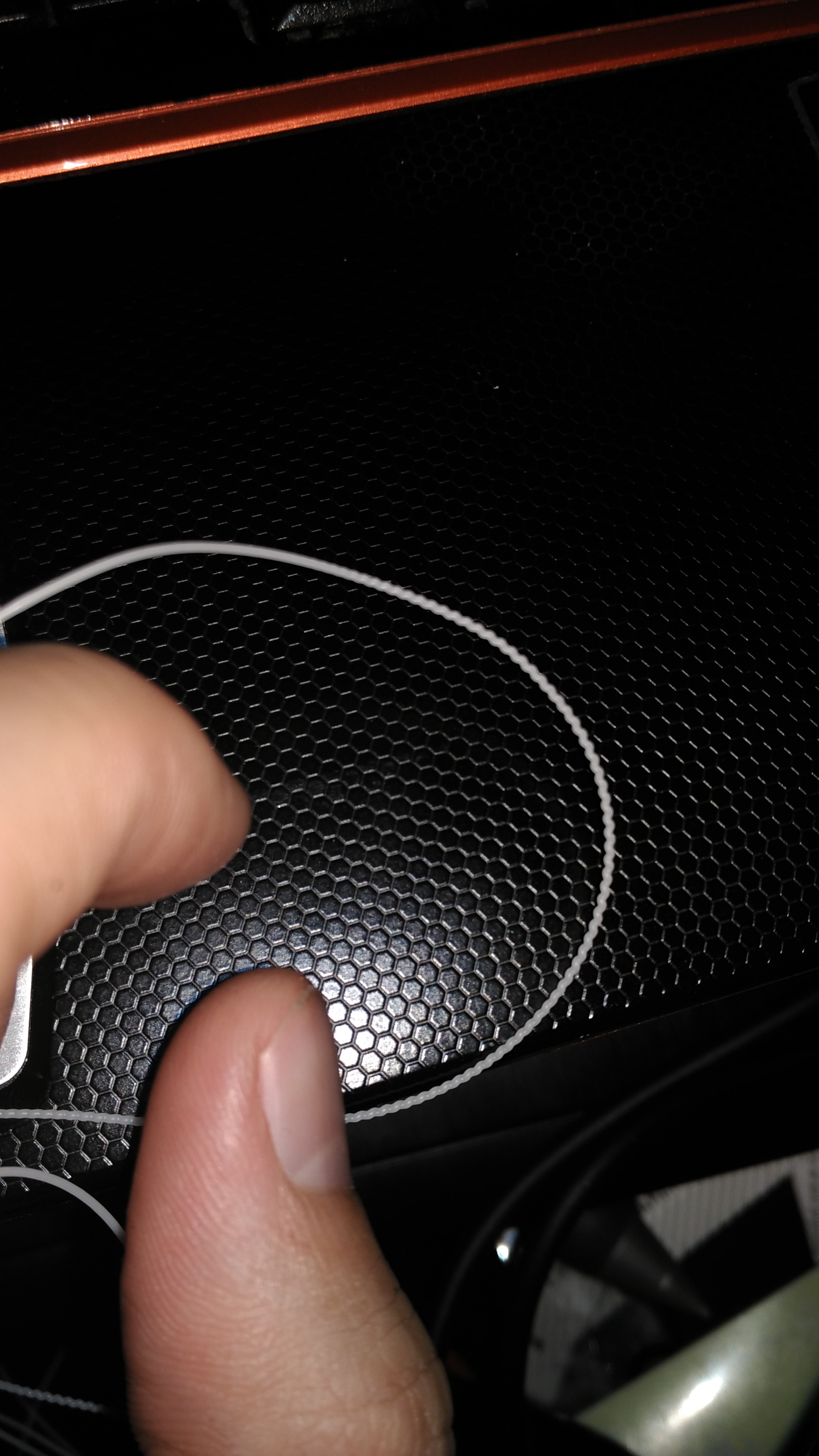

Here my extrusion, there I some kind of waves/spins…

Here my filament tip after retracted…

@eric

Both looks normal.

With different extrusion speeds and temperature it looks different when just extruding.

Sometimes it just curls directly at the nozzle making a nice string mess.

Only worry when your print result shows defects. But mostly its a print speed and temperature origin.

Whereas scientsit434 looks more like feeder or partly clogged nozzle problem.

I have so many unexplainable and unsolvable partly clogged nozzle problems, that I now have one nozzle for every material I print and try not to change brands.

I switched PLA to ABS, since that extrusions are Inconsistents. I tried 210C / 230C / 250C… Settings did not change flow extrusion.

Worth now, I get same result with PLA.

I thought it was the clue of my issue because since this weird shapes, I can’t finish a print normally, most of the time, motors stop feed nozzle.

I should mesure it, but nearly for 100mm extrusion, it is missing 20mm. And sometimes it did not extrude…

I will tried to clean my nozzle in acetone bath (I don’t have extra nozzle)

That sounds bad.

Do you sometimes hear a clicking sound? That is the filament gear slipping one teeth. Than you definetly know its nozzle or dirty gears.

It could be related to switching Material and some residues, now burned in from PLA or other foreign particle. Thats why some brands tell to use special cleaning filament after material change, to reduce those problems.

Acetone will only affect ABS and not PLA. So no help.

When dealing with clogged nozzles I heat it up and use drill / piano wire (you have to look if 0.3mm or 0.35mm is fitting; I had differences with my nozzles) plus cold pull method. That means heat it up, drill and than turn off heater and when temperature is like 160° quickly retract. You will see a bigger tip at the end that you maybe have to forcefully pull through the running gears. It sometimes is too big to be transported by itself. Repeat a few times and hopefully get better print results.

But as already said I have a few nozzles that will not print properly anymore regardless what I tried. They can only extrude 95% which is fine for vase mode, but not good for everything else that has surfaces. After cleaning they print fine for a few minutes and than I can start hearing those clicking noises from slipping gear teeth.